Content

- 1 Overview: what “producing dried cabbage” involves

- 2 Pre-processing steps common to all methods

- 3 Hot-air (tray / tunnel) drying — the industrial workhorse

- 4 Freeze-drying (lyophilization) — premium quality preservation

- 5 Vacuum drying and vacuum belt / tray dryers

- 6 Microwave-assisted and infrared drying — speed and energy efficiency

- 7 Drum drying and spray/drying of purees — for powders and instant mixes

- 8 Osmotic dehydration and combined methods

- 9 Comparative table: method, quality, cost and typical use

- 10 Quality control targets and final moisture

- 11 Packaging, storage and handling after drying

- 12 Selecting a process: key decision factors

- 13 Conclusion: match method to product goals

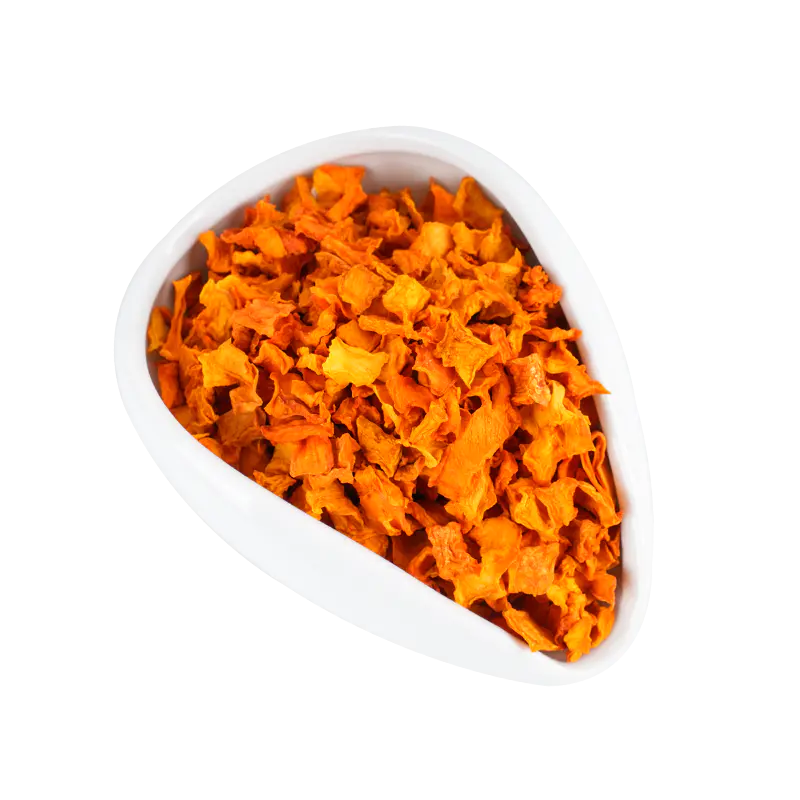

Overview: what “producing dried cabbage” involves

Producing dried cabbage is more than removing water. A reliable process preserves color, texture and flavor while meeting food-safety and shelf-life targets. Typical production combines pre-treatment (sorting, washing, shredding, blanching), a chosen drying technology, and final handling (cooling, screening, packaging). The choice of drying method depends on target product form (flakes, dices, powder), production scale, capital cost and desired sensory quality.

Pre-processing steps common to all methods

Before drying, cabbage must be prepared to promote uniform drying and reduce microbial load. Typical steps include:

- Sorting and trimming: remove outer, damaged leaves and foreign matter to avoid quality variation.

- Washing and sanitizing: remove soil and reduce surface microbes; often followed by draining or using a centrifugal dewaterer for bulk lines.

- Cutting or shredding: cut to target particle size—slices, strips or fine shreds—so thickness and exposed surface area match the drying method.

- Blanching or steam treatment: short heat treatment (typically 1–3 minutes at 85–95°C or steam) inactivates enzymes that cause color and flavor loss; time/temperature depend on cut size and final product goal.

- Optional pre-treatments: sulfite or ascorbic acid dips, osmotic dehydration (sugar/salt bath) or vacuum impregnation to retain color and reduce drying time for specific product lines.

Hot-air (tray / tunnel) drying — the industrial workhorse

Hot-air drying is the most common commercial choice for sliced or shredded cabbage due to its simplicity and scalability. Leaf pieces are conveyed on trays or belts through controlled heated airflow. Typical operating air temperatures range from 60°C to 90°C depending on cut thickness, with drying times from 2 to 8 hours for tray dryers and shorter for high-velocity tunnel dryers.

Advantages and process notes

Hot-air dryers are lower-cost to install and operate compared with freeze-dryers. They allow high throughput and are adaptable to continuous lines. Proper airflow design and humidity control reduce case hardening (surface hardening that traps moisture), and staged drying (higher temperature early, lower later) improves texture.

Drawbacks

Hot-air drying can cause greater color and flavor loss and shrinkage versus gentle methods. Enzyme inactivation by blanching is nearly essential to prevent off-color during storage.

Freeze-drying preserves color, shape and volatile flavor compounds by freezing the product and removing ice via sublimation under vacuum. The result is a highly porous, rehydratable product with excellent sensory recovery. Typical cycles are long—often 24–72 hours—and energy and equipment costs are high.

Best uses

Freeze-dried cabbage is ideal for high-end instant soups, ready-meals, gourmet snacks and products where rapid, near-fresh rehydration is required. It is also preferred for lightweight emergency rations where rehydration speed matters.

Limitations

High capital and operating expenses limit freeze-drying to premium product lines or small-batch specialty items. Fragility of the final product also requires careful packaging to prevent crushing.

Vacuum drying and vacuum belt / tray dryers

Vacuum drying lowers the boiling point of water, enabling drying at lower temperatures (typically 40–70°C) that better protect color and nutrients. Vacuum belt or tray dryers are used where heat-sensitive attributes are important. Drying times are typically shorter than convective hot-air for similar quality outcomes.

Advantages

Lower thermal damage, improved retention of volatile compounds, and reduced oxidation risk. Vacuum systems can be combined with gentle mechanical dewatering to speed throughput.

Considerations

Capital costs are higher than simple hot-air units; maintenance of vacuum pumps and seals is required. Design must prevent product sticking to heated surfaces.

Microwave-assisted and infrared drying — speed and energy efficiency

Microwave drying heats water internally, while infrared provides surface heating; both can be used alone or together with convective air to shorten drying time and improve energy efficiency. Combined microwave-infrared-convective systems are gaining traction for vegetables.

Operational benefits

Faster drying reduces thermal exposure, which helps preserve color and nutrients. Microwave energy can reduce case-hardening by driving moisture from the interior, improving overall moisture uniformity.

Technical cautions

Microwave drying requires precise control to avoid hotspots and local overheating. Equipment and safety shielding add to capital cost; pilot testing is essential before scaling.

Drum drying and spray/drying of purees — for powders and instant mixes

When the intended product is a powder or instant mix, cabbage can be cooked into a puree and dried into flakes or powder via drum drying or spray drying (spray drying is more common for liquid blends with carriers). Drum drying produces thin flakes that mill into powder; final moisture targets are usually below 6%.

Advantages

Drum and spray methods produce free-flowing powders suitable for seasoning blends, instant soups and dry mixes and are highly scalable with continuous operation.

Drawbacks

Thermal exposure during cooking and drying reduces volatile aromas and some nutrients; carrier materials (maltodextrin) are often needed for spray drying to improve powder properties.

Osmotic dehydration and combined methods

Osmotic dehydration immerses cabbage in hypertonic solutions (salt or sugar) to remove water prior to drying. While used less commonly for cabbage, it can reduce energy needs in subsequent drying and preserve texture. Often combined with convective or microwave drying for better final quality.

Comparative table: method, quality, cost and typical use

|

Method |

Quality (color/texture) |

Relative cost |

Common product form |

|

Hot-air (tray/tunnel) |

Moderate |

Low–medium |

Slices, shreds, dices |

|

Freeze-drying |

Excellent (near-fresh) |

High |

Crisp pieces, rehydratable chunks |

|

Vacuum drying |

Good |

Medium–high |

Shreds, dices |

|

Microwave / Infrared |

Good – variable |

Medium |

Shreds, specialized pieces |

|

Drum / Spray (puree → powder) |

Moderate (powder form) |

Medium |

Powder, flakes |

Quality control targets and final moisture

Final moisture for shelf-stable dried cabbage typically sits between 4% and 8% (w.b.), depending on product form and intended shelf life. Water activity should be controlled to prevent microbial growth and Maillard reactions—target aw values are commonly below 0.6 for long-term stability. Color, rehydration ratio, and particle-size distribution are routine QC checks.

Packaging, storage and handling after drying

Immediately after drying, products must be cooled to ambient temperature and packaged in moisture-barrier materials (foil pouches, laminated bags or lined bulk sacks). Modified atmosphere packaging (nitrogen flushing) and oxygen scavengers further protect color and volatiles, particularly for freeze-dried pieces and powders.

Selecting a process: key decision factors

Choose the drying route based on: desired product form and rehydration quality; throughput and capital limits; allowable operating cost; and end-use (consumer convenience vs. ingredient use). Pilot trials are essential: test raw-material variability, blanching recipes, and drying curves to dial in cycle times, temperatures and humidity profiles before full-scale investment.

Conclusion: match method to product goals

Multiple validated drying technologies can produce high-quality dried cabbage. Hot-air drying offers economy and scale; freeze-drying gives premium rehydration and appearance; vacuum and microwave-assisted systems balance quality and speed. With proper pre-treatment, careful control of moisture and packaging, manufacturers can deliver dried cabbage products tailored for soups, instant meals, snacks, seasonings or nutritional mixes.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168