Large-scale food processors manage complex supply chains where transport cost, cold-chain capacity, inventory turnover and product waste directly affect margins. Replacing or supplementing fresh cabbage with dried cabbage can change many of these levers. The sections below break down concrete logistical and storage benefits, quantify their operational impact, and outline practical considerations for implementation at scale.

Content

- 1 Lower transport weight and volume

- 2 Elimination or reduction of cold-chain requirements

- 3 Extended shelf life and reduced spoilage

- 4 Simplified inbound handling and reduced labor

- 5 Improved supply resilience and procurement flexibility

- 6 Packaging efficiencies and optimized storage density

- 7 Reduced waste and lower disposal costs

- 8 Quality assurance and traceability benefits

- 9 Comparative logistics table: fresh vs dried cabbage

- 10 Implementation considerations and risk mitigations

- 11 Practical checklist for logistics teams

- 12 Conclusion: logistic leverage from dried cabbage

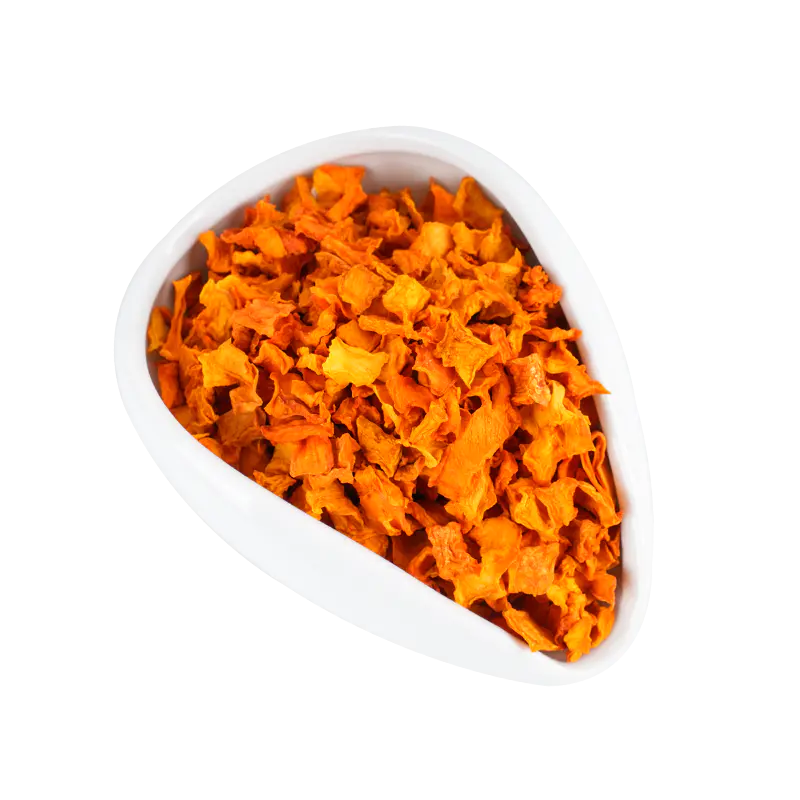

Lower transport weight and volume

Water accounts for most of the mass and bulk of fresh vegetables. Dehydration removes the bulk water, producing a product that occupies far less cubic space and weighs substantially less per unit of usable solids. Lower weight and smaller pallet footprints reduce freight costs (per usable kilogram), enable higher truck or container utilization, and lower incidence-based shipping surcharges tied to volume or weight breaks.

Quantifiable impact on freight and handling

As a rule of thumb, dried cabbage can reduce transport weight by 70–90% compared with fresh on a per-nutrient basis. For long-haul or cross-border shipments this weight reduction can translate into 40–70% lower freight spend for the same functional ingredient delivered to the processing facility.

Elimination or reduction of cold-chain requirements

Fresh cabbage typically requires refrigerated trucks and cold storage to retain quality. Dried cabbage is shelf-stable at ambient temperatures when properly packaged. Removing refrigeration from receiving, storage, and transport eliminates refrigeration energy use, reduces dependence on limited cold-room space, and removes temperature-excursion risks during transit.

Operational advantages of ambient handling

Ambient-storage capability simplifies scheduling (no temperature-sensitive narrow windows), allows use of standard warehousing (often cheaper per m²), and reduces refrigeration maintenance, monitoring costs and the complexity of HACCP temperature logging for inbound ingredients.

Extended shelf life and reduced spoilage

Dried cabbage typically attains low moisture content and water activity levels that inhibit microbial growth and enzymatic spoilage. Longer shelf life reduces inventory turnover pressure, allows bulk purchasing and seasonal stockpiling, and lowers discard rates due to rot, sprouting or transit damage common with fresh produce.

Inventory management benefits

Longer shelf life enables centralized purchasing strategies, reduces emergency replenishment shipments, and smooths production scheduling. It also reduces the need for safety stock buffers that are otherwise required to cover spoilage and supply volatility.

Simplified inbound handling and reduced labor

Fresh vegetables require sorting, trimming, washing lines, and often peeling—operations that require labor, line space and contamination controls. Dried cabbage arrives preprocessed (shredded, diced or powdered as required), cutting out many manual or automated prep steps and consequently reducing labor hours, equipment footprint and cleaning cycles in the raw-material area.

Reduced line complexity

Removing washing and peeling stations lowers water usage and wastewater treatment needs, simplifies sanitation regimes, and lowers scheduled downtime associated with those operations.

Improved supply resilience and procurement flexibility

Because dried cabbage stores well, processors can purchase in larger quantities during harvest peaks or favorable pricing windows. This reduces exposure to seasonal shortages, weather-driven crop failures or sudden spot-price spikes, improving supply security and negotiating leverage with suppliers.

Hedging and contract advantages

Bulk purchases of dried material can be covered by long-term contracts or warehoused to support promotional plans and peak demand, allowing better cost forecasting and tighter margin control.

Packaging efficiencies and optimized storage density

Dried cabbage is typically packed in moisture-barrier bags, lined sacks, or bulk supersacks designed for high pallet stacking. This standardized packaging enables predictable pallet patterns, higher stacking heights, and improved cubic utilization of warehouse space versus loose, irregularly shaped fresh crates and bins.

Compatibility with automated warehousing

Uniform bagged or boxed formats integrate readily with automated forklift, pallet shuttle, and pick-and-place systems, reducing manual handling and accelerating put-away and retrieval cycles.

Reduced waste and lower disposal costs

Fresh cabbage generates peelings, trimmings and spoiled product that require disposal or by-product processing. Dried cabbage minimizes incoming waste and reduces outbound waste from inventory expiry. Lower waste volumes reduce disposal costs and can reduce costs associated with on-site composting or biogas systems dedicated to organic waste streams.

Quality assurance and traceability benefits

Dried ingredient suppliers commonly deliver products with certificates of analysis (COAs) stating moisture, microbial counts, and particulation. Consistent specs reduce the frequency of incoming rejections and speed QA sampling. Packaged lots with clear lot codes improve traceability and recall management compared with mixed-batch fresh produce deliveries.

Comparative logistics table: fresh vs dried cabbage

|

Logistics metric |

Fresh cabbage |

Dried cabbage |

|

Transport weight per usable kg |

High |

Low (70–90% reduction) |

|

Cold-chain required |

Yes |

No (ambient) |

|

Shelf life (typical) |

Days–weeks |

Months–years |

|

Warehousing complexity |

High (refrigeration, sorting) |

Low (stackable packaged units) |

|

Incoming QA burden |

High (visual, microbial) |

Lower (COA + spot checks) |

Implementation considerations and risk mitigations

Moving to dried cabbage requires changes to procurement, inventory, and production planning. Key actions include validating rehydration performance at scale, updating bills of materials and recipes, adjusting supplier quality agreements to include moisture and particle-size tolerances, and training warehouse staff on moisture control and desiccant handling. Dust management and electrostatic risk during bag handling must be addressed via enclosed transfer points and extraction where needed.

Practical checklist for logistics teams

- Compare landed cost per usable kilogram including freight, storage, and waste for both fresh and dried options.

- Pilot small bulk shipments to confirm packaging, palletization and put-away routines.

- Update ERP inventory profiles to reflect shelf life and rotate dried stock differently from perishables.

- Coordinate QA and R&D to confirm sensory and processing equivalence for intended applications.

Conclusion: logistic leverage from dried cabbage

For large-scale food processors, dried cabbage delivers measurable logistical and storage benefits: significantly lower transport and storage costs, removal of refrigeration dependence, longer shelf life that enables strategic purchasing, simplified warehouse operations, lower waste, and improved traceability. Careful pilot testing and supplier agreements ensure the operational transition captures these benefits without compromising product quality or regulatory compliance.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168