This article focuses on practical, actionable knowledge about using dried chives to enhance flavor in contemporary culinary contexts — from commercial kitchens and ready-meal formulation to retail spice blends and snack seasonings. It covers how drying and processing influence flavor chemistry, rehydration and infusion techniques that maximize aroma release, pairing and dosing guidelines, and operational tips for chefs and food technologists seeking consistent results at scale.

Content

- 1 Flavor chemistry: what remains and what changes when chives are dried

- 2 Maximizing aroma and flavor release: rehydration and application techniques

- 3 Applications where dried chives outperform fresh

- 4 Pairing, dosing and sensory balancing

- 5 Shelf life, packaging and quality control for consistent performance

- 6 Processing innovations that preserve or enhance flavor

- 7 Comparison: dried chives vs fresh chives — practical trade-offs

- 8 Operational recommendations for chefs and product developers

Flavor chemistry: what remains and what changes when chives are dried

The characteristic onion-garlic aroma of chives comes from sulfur-containing volatiles and a range of light terpenes and aldehydes. Drying reduces overall volatile content but concentrates non-volatile flavor precursors and umami-enhancing components. Thermal or sun drying typically causes loss of the most fragile volatiles, while low-temperature dehydration (e.g., vacuum or freeze drying) better preserves aroma compounds. Understanding which compounds survive drying explains why dried chives perform differently from fresh: they deliver a steadier, less pungent aroma with stronger cooked/umami notes, making them suitable for processed foods where an intense fresh onion hit is undesirable.

Processing variables that impact retained flavor

Key processing factors include drying temperature, drying rate, leaf blanching before dehydration, particle size after milling, and post-dry storage conditions. Blanching can soften enzymes that otherwise degrade desirable compounds, but excessive blanching reduces green notes. Finer milling increases surface area and accelerates aroma release but also speeds up oxidation; therefore, selection of particle size must balance rapid rehydration and shelf stability.

Maximizing aroma and flavor release: rehydration and application techniques

Dried chives can be used directly or rehydrated depending on the application. For fresh-like appearance and texture in hot dishes, rehydrate using cold water (mild rehydration for quick texture recovery) or warm water (faster and fuller rehydration). For flavor-first applications such as sauces, soups or dressings, bloom dried chives in warm fat (butter or oil) or warm liquid to extract lipid-soluble volatiles and intensify mouthfeel. Timing matters: add rehydrated or bloomed chives toward the end of cooking to preserve volatile aromatics while still integrating flavor.

Practical rehydration guidelines

Typical baseline rehydration ratios range from 1:6 to 1:10 (dried to water by weight) depending on particle size and desired texture; allow 10–20 minutes for full rehydration at room temperature or 2–5 minutes in warm liquid. For commercial sauces, pre-soaking in portioned brine or oil reduces batch variability and speeds production lines.

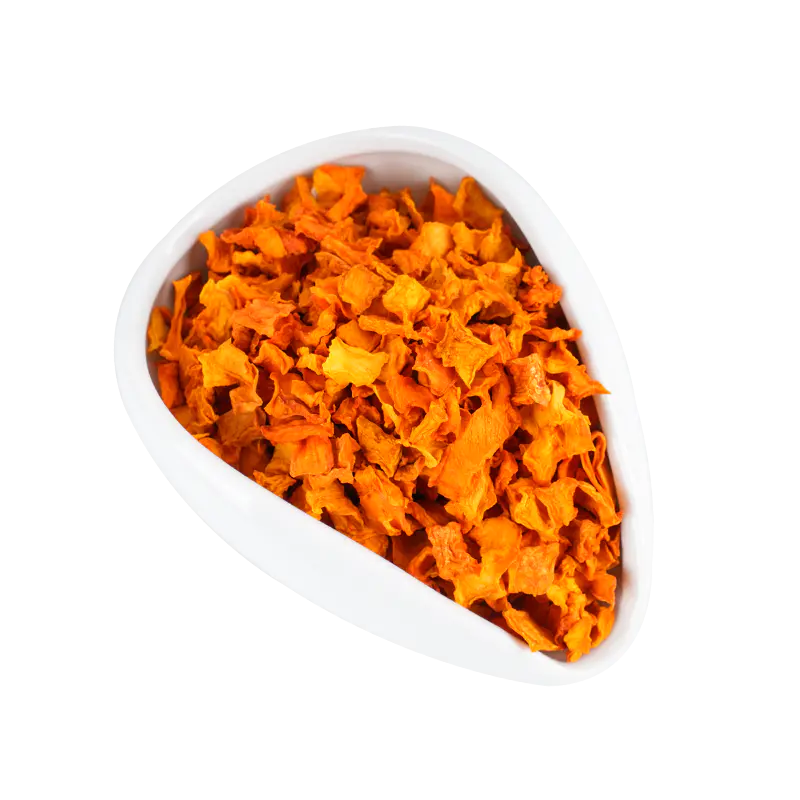

Applications where dried chives outperform fresh

Dried chives are particularly effective where consistency, shelf life and predictable flavor intensity are required. Examples include seasoning blends, instant soup mixes, ready meals, snack powders, and dry rubs. Their lower moisture content prevents microbial growth and reduces the logistics of cold chain management. They also integrate well in powdered seasoning mixes where fresh herbs would be impractical.

- Seasoning blends & snack coatings — provide stable onion-like notes without clumping when formulated with anti-caking agents.

- Instant soups & meal kits — rehydrate quickly and contribute soluble flavor compounds that survive drying.

- Sauces & compound butters — when bloomed in fat, deliver a rounded, integrated chive flavor that holds under gentle heat.

Pairing, dosing and sensory balancing

Because dried chives have a milder, more cooked character than fresh, dose them slightly higher by weight to achieve comparable perceived flavor intensity in cold applications. However, avoid overuse: excessive dried chives can impart bitterness or dried-herb notes. Pairings that amplify chive flavor include dairy fats (cream, butter, cultured products), citruses for brightness, and umami ingredients (miso, yeast extracts) which harmonize with chive’s savory undertones.

Commercial dosing examples

In dry seasoning blends, start with 0.3–0.8% dried chives by weight and adjust by sensory evaluation. For ready-to-eat sauces, a starting point is 0.5–1.2% rehydrated-equivalent concentration. Always run bench-scale sensory panels to align dosing with target consumer profiles and label expectations.

Shelf life, packaging and quality control for consistent performance

Oxidation and moisture uptake are primary threats to dried chive quality. Effective packaging uses low-oxygen barrier films, desiccants when appropriate, and nitrogen flushing to extend aroma life. Store in cool, dark conditions — every 10°C increase in storage temperature can significantly accelerate volatile loss. Establish quality control checks for moisture content, volatile aroma retention (GC headspace profiling if available), microbial limits, and sensory acceptance before approving lots for production.

Simple on-site QC checks

Perform a quick visual check for color uniformity and absence of foreign matter, a tactile test for crispness (indicating low moisture), and a simple sniff test comparing lot aroma intensity to a reference sample. Record lot numbers and use first-expire-first-out (FEFO) rotation in production to maintain consistency.

Processing innovations that preserve or enhance flavor

Emerging techniques such as vacuum drying, freeze drying, and microwave-assisted drying reduce thermal exposure and preserve labile aromatics. Microencapsulation of chive extracts in maltodextrin or protein carriers can protect volatile compounds during storage and control release during rehydration or when exposed to heat. For food manufacturers, investing in premium dried chive formats (e.g., freeze-dried flakes or encapsulated powders) can significantly improve sensory outcomes in high-value products.

Comparison: dried chives vs fresh chives — practical trade-offs

|

Attribute |

Dried Chives |

Fresh Chives |

|

Shelf life |

12–36 months (with proper packaging) |

Days to 2 weeks (refrigerated) |

|

Flavor profile |

Milder, cooked/umami notes |

Bright, green, sharp |

|

Logistics |

Stable, no cold chain |

Requires refrigeration and fast turnover |

|

Best uses |

Dry blends, instant meals, long-shelf products |

Fresh garnishes, cold dishes, high-end plating |

Operational recommendations for chefs and product developers

For kitchen teams, standardize a rehydration protocol and maintain a sensory reference panel to ensure batch-to-batch consistency. For product developers, partner with suppliers who provide technical sheets with moisture content, particle size distribution, and headspace GC aroma data if possible. When scaling, trial encapsulated or freeze-dried formats to evaluate whether the premium cost is justified by improved flavor retention and extended shelf stability.

Checklist before specification

Request sample lots for pilot runs, verify packaging barrier properties, confirm storage recommendations, and perform accelerated shelf-life testing at elevated temperatures to predict aroma retention. Include sensory acceptance as a pass/fail criterion in your specification prior to approving a supplier.

Dried chives are a versatile and practical ingredient for modern culinary applications when their processing, rehydration and formulation behavior are properly understood. By selecting the right drying technology, controlling particle size, optimizing rehydration or blooming methods, and implementing robust packaging and QC, chefs and food manufacturers can harness dried chives to deliver consistent, desirable flavor across a wide range of product types.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168