This article provides a detailed comparison of dried chives and fresh chives from the perspective of flavor stability, cost efficiency, storage requirements, and suitability for different culinary and industrial applications. Instead of basic introductions, the focus is on practical decision-making insights for chefs, food manufacturers, and procurement teams seeking consistent performance in both small-scale and commercial environments.

Content

- 1 Flavor stability: how each format behaves during storage and cooking

- 2 Cost efficiency: evaluating ingredient performance over time

- 3 Comparison table: flavor stability and cost-related attributes

- 4 Operational considerations for culinary teams and manufacturers

- 5 Rehydration and usage efficiency in recipe development

- 6 Packaging, storage control and long-term quality management

- 7 Choosing between dried and fresh chives based on operational goals

Flavor stability: how each format behaves during storage and cooking

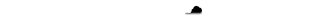

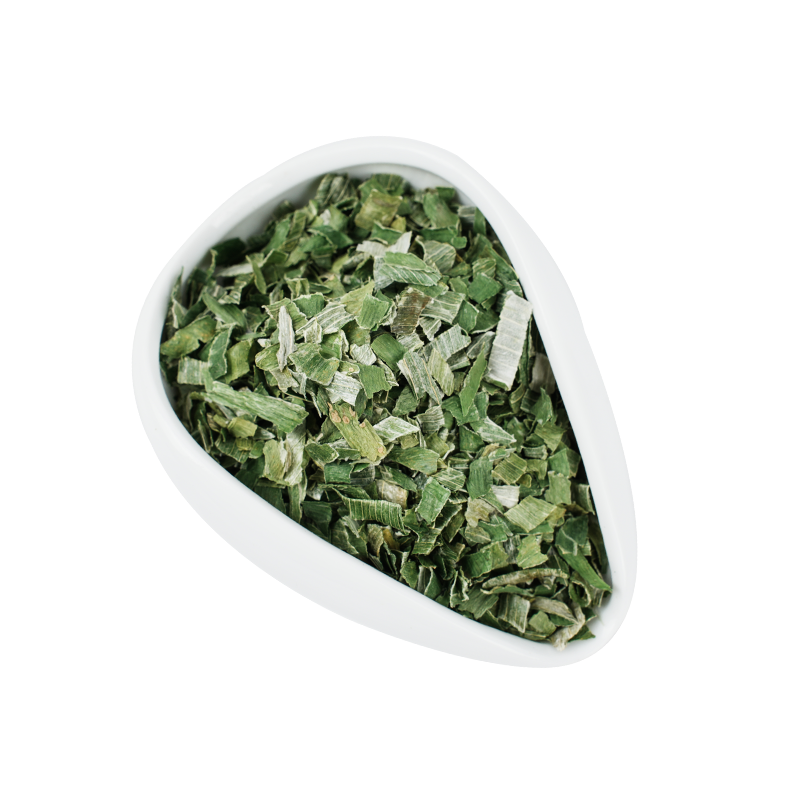

Flavor stability is the most significant point of differentiation between dried and fresh chives. Fresh chives contain delicate sulfur-based volatiles that degrade quickly when exposed to air, temperature fluctuations, or mechanical handling. As a result, their aroma intensity drops noticeably within days, even under refrigeration. Dried chives, by contrast, retain flavor through moisture reduction, which slows enzymatic activity and volatile breakdown. When processed using low-temperature dehydration, the remaining flavor compounds remain stable for months or even years, making them reliable for long-term production cycles.

Behavior in cooked and prepared foods

Fresh chives release bright, green, onion-like notes when added at the end of cooking or used as garnish. However, during extended heating, these fresh volatiles dissipate rapidly, often leaving minimal flavor behind. Dried chives, on the other hand, have a more subdued but persistent aromatic profile. Their flavor integrates better into simmered dishes, dry mixes, and processed foods where heat exposure is unavoidable. Rehydration also leads to a steady release of flavor that remains stable throughout the cooking or manufacturing process.

Cost efficiency: evaluating ingredient performance over time

Cost efficiency extends beyond purchase price. Fresh chives incur losses through trimming, rapid spoilage, and moisture weight that contributes no flavor. Dried chives, with moisture levels typically below 10%, offer concentrated flavor delivery per unit weight. When recalculated on a flavor-equivalent basis, dried chives usually provide a lower cost of use. The absence of refrigeration and reduced transportation weight further minimize operational costs in commercial settings.

Breakdown of typical cost factors

Fresh chives require frequent replenishment, cold-chain logistics, and labor for cleaning or chopping. Dried chives eliminate these requirements and reduce waste from spoilage. For high-volume kitchens or food manufacturers, this difference becomes significant over extended production periods.

|

Attribute |

Dried Chives |

Fresh Chives |

|

Shelf life |

12–36 months, stable when sealed |

5–14 days even under refrigeration |

|

Flavor retention over time |

High; slow degradation due to moisture removal |

Low; volatile loss begins within hours of harvest |

|

Cost efficiency per flavor unit |

High; concentrated flavor and minimal waste |

Low; moisture weight and spoilage increase costs |

|

Storage requirements |

Cool, dry room-temperature storage |

Refrigeration required |

|

Best application types |

Dry blends, instant meals, sauces, processed foods |

Fresh garnishes, salads, finishing touches |

Operational considerations for culinary teams and manufacturers

The operational differences between dried and fresh chives influence workflow design. Fresh chives require immediate handling, careful storage, and rapid use to prevent discoloration and flavor decline. Dried chives offer flexible batching, simplified inventory management, and compatibility with automated production systems. For large-scale manufacturers, dried chives eliminate variability caused by seasonal supply fluctuations and quality inconsistencies.

When dried chives offer better performance

Dried chives are especially advantageous in products exposed to heat, humidity, or extended storage. Examples include dehydrated soup mixes, seasoning packets, instant noodles, freeze-dried meals, and long-shelf ready-meals. Their ability to retain flavor under these conditions ensures predictable output in taste-sensitive applications.

Rehydration and usage efficiency in recipe development

Rehydration allows dried chives to closely mimic the appearance of fresh chives while maintaining a more stable flavor profile. Typical rehydration ratios range from 1:6 to 1:10 (dried to water). For culinary teams, using pre-measured rehydrated batches improves workflow consistency. In industrial food formulation, integrating dried chives directly without rehydration often yields better dispersion and batch uniformity.

Practical usage scenarios

- In sauces and broths, dried chives release flavor steadily during simmering, avoiding the rapid fade seen with fresh chives.

- In seasoning blends, dried chives maintain color, aroma, and particle uniformity without moisture-induced clumping.

- In cold dishes, rehydrated dried chives can achieve similar visual appeal with greater storage reliability.

Packaging, storage control and long-term quality management

Dried chives require protection from oxygen, moisture and light to maintain flavor stability. Packaging with high barrier properties, nitrogen flushing, or inclusion of desiccant packets helps prolong aroma retention. Fresh chives, in contrast, are extremely sensitive to dehydration, microbial growth, and mechanical stress, necessitating cold distribution networks and quick turnover. The difference in logistic demands heavily influences cost efficiency over time.

Quality control guidelines

For dried chives, routine checks include moisture content, aroma intensity, particle uniformity, and color stability. For fresh chives, verification focuses on firmness, chlorophyll degradation, and visible microbial contamination. Each format has distinct QC checkpoints, but dried chives allow more predictable control over long-term inventory.

Choosing between dried and fresh chives based on operational goals

Selecting dried or fresh chives depends entirely on the desired flavor profile, production intensity, and shelf-life requirements. Fresh chives provide bright, green aromatics suitable for immediate-service dishes, while dried chives offer stability and cost efficiency crucial for manufacturing, large kitchens, and shelf-stable foods. Understanding these distinctions enables chefs and developers to specify the most effective format for their needs, balancing flavor integrity with economic performance over time.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168