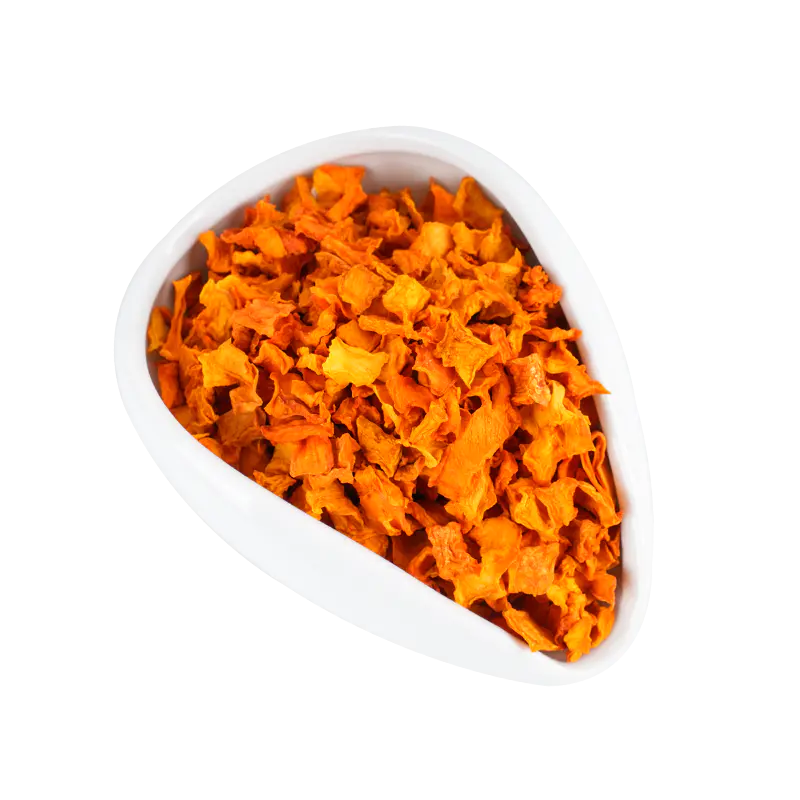

Dehydrated sweet potato powder is a dry, finely milled ingredient made from fresh sweet potatoes that have been washed, peeled, sliced, dehydrated, and ground. The dehydration process removes most of the moisture while retaining the natural starches, sugars, color, and characteristic flavor of sweet potato. Compared with fresh roots, the powdered form offers easier storage, longer shelf life, and more consistent application in industrial food processing.

Production typically starts with raw material selection, focusing on mature sweet potatoes with stable sugar content and color. After dehydration at controlled temperatures, the dried slices are milled and sieved to achieve uniform particle size. This controlled process supports consistent rehydration behavior and predictable performance in downstream applications.

Content

- 1 Key Physical and Functional Characteristics

- 2 Particle Size and Its Impact on Application Performance

- 3 Applications in Food Manufacturing

- 4 Use in Animal Feed and Pet Food Formulations

- 5 Handling, Storage, and Shelf Stability Considerations

- 6 Formulation Tips for Consistent Results

- 7 Quality Control and Specification Focus

Key Physical and Functional Characteristics

Dehydrated sweet potato powder combines functional starch properties with natural sweetness and color. These characteristics influence how it performs in baking, extrusion, blending, and rehydration-based formulations.

- Low moisture content supports extended storage and reduces microbial risk.

- Natural starch contributes to thickening and binding when hydrated.

- Mild natural sweetness allows partial sugar reduction in some formulations.

- Orange to yellow color tones provide visual appeal without synthetic additives.

Particle Size and Its Impact on Application Performance

Particle size is a practical parameter when selecting dehydrated sweet potato powder for specific uses. Fine powders disperse more evenly in liquid systems, while coarser grades may contribute visible texture or structure.

| Fine Powder | Smooth beverages, sauces, baby food |

| Medium Powder | Bakery mixes, instant soups |

| Coarse Powder | Snack coatings, textured fillings |

Applications in Food Manufacturing

In food manufacturing, dehydrated sweet potato powder functions as both a flavor component and a functional ingredient. Its dry format allows direct dosing into dry blends or controlled rehydration during processing.

Bakery and Baked Snacks

In bakery products, the powder can be incorporated into flour blends to add color, mild sweetness, and moisture retention after baking. It supports dough structure by interacting with wheat or alternative flours.

Instant and Convenience Foods

Instant soups, mashed products, and meal replacements use dehydrated sweet potato powder for quick rehydration and consistent flavor. The powder dissolves or softens rapidly in hot water systems.

Use in Animal Feed and Pet Food Formulations

Beyond human food, dehydrated sweet potato powder is applied in animal feed and pet food as a carbohydrate source and natural color contributor. Its dry form simplifies inclusion in extrusion and pelleting processes.

- Supports uniform nutrient distribution in dry feed mixes.

- Contributes palatability through natural aroma and taste.

- Allows easier storage compared with fresh root ingredients.

Handling, Storage, and Shelf Stability Considerations

Proper handling and storage help maintain the quality of dehydrated sweet potato powder. As a hygroscopic material, it readily absorbs moisture if exposed to humid environments.

Storage in sealed, moisture-resistant packaging under cool and dry conditions helps preserve flowability, color stability, and functional performance over time. Industrial users often include desiccants or nitrogen flushing for additional protection.

Formulation Tips for Consistent Results

When integrating dehydrated sweet potato powder into formulations, gradual addition and controlled hydration support uniform dispersion. Pre-blending with other dry ingredients can reduce clumping in liquid systems.

- Match particle size to the target texture of the final product.

- Adjust water ratios to account for starch swelling behavior.

- Test color impact in pilot batches before full-scale production.

Quality Control and Specification Focus

Quality control for dehydrated sweet potato powder typically centers on moisture level, particle size distribution, color consistency, and absence of foreign matter. These parameters directly affect processing behavior and end-product appearance.

Clear specification alignment between supplier and buyer supports stable sourcing and predictable production outcomes, particularly for large-scale or export-oriented food manufacturing operations.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168