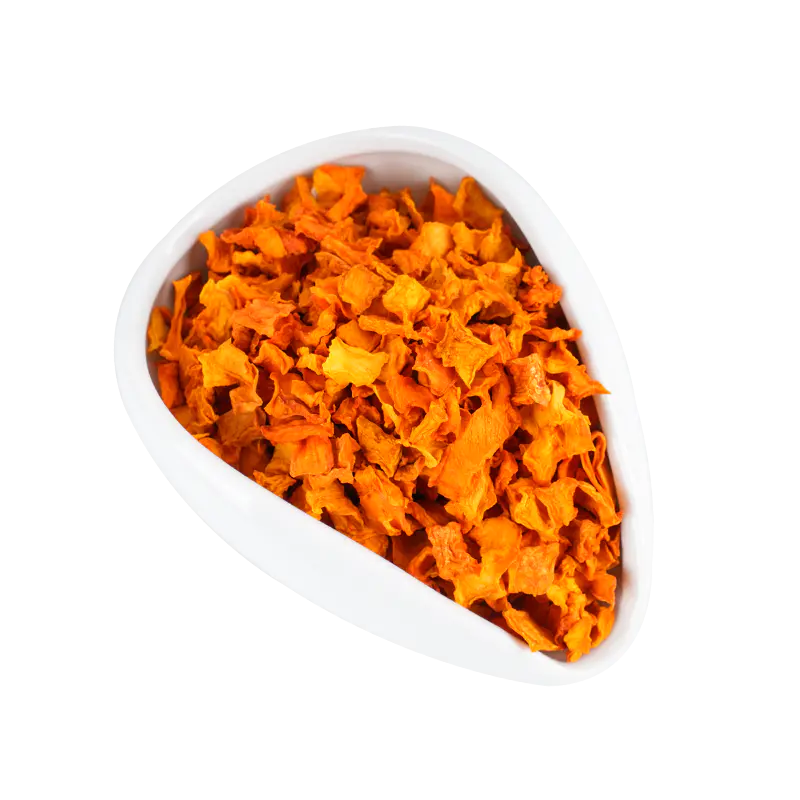

Dehydrated pumpkin strips represent a versatile, nutrient-dense food preservation method that transforms fresh pumpkin into shelf-stable strips perfect for snacking, cooking, and long-term storage. This dehydration process concentrates the natural sweetness and nutritional value of pumpkin while creating a lightweight, space-efficient product that maintains quality for months or even years when properly stored. Whether you're looking to preserve autumn's pumpkin harvest, create healthy snacks, or stock your pantry with convenient cooking ingredients, understanding the techniques and applications of dehydrated pumpkin strips opens up numerous culinary possibilities.

Content

- 1 Understanding Dehydrated Pumpkin Strips

- 2 Preparing Pumpkin for Dehydration

- 3 Dehydration Methods and Techniques

- 4 Storage Methods and Shelf Life

- 5 Rehydrating Dehydrated Pumpkin Strips

- 6 Culinary Applications and Recipe Ideas

- 7 Troubleshooting Common Issues

- 8 Cost-Effectiveness and Yield Calculations

- 9 Safety Considerations and Best Practices

- 10 Comparing Homemade Versus Commercial Products

Understanding Dehydrated Pumpkin Strips

Dehydrated pumpkin strips are thin slices of pumpkin flesh that have had their moisture content reduced to approximately five to ten percent through controlled drying processes. This dramatic moisture reduction inhibits bacterial growth, enzyme activity, and mold development, effectively preserving the pumpkin for extended periods without refrigeration. The dehydration process concentrates the pumpkin's natural sugars, creating a sweeter, more intense flavor profile compared to fresh pumpkin while maintaining most of the original nutritional content.

The ideal pumpkin varieties for dehydration include sugar pumpkins, pie pumpkins, and other dense-fleshed cultivars rather than the large carving pumpkins commonly used for Halloween decorations. These cooking varieties contain less water, more flesh density, and superior flavor compared to their ornamental counterparts. The flesh should be firm, vibrant orange in color, and free from blemishes or soft spots. Mature pumpkins harvested after their rinds have hardened produce the best dehydrated strips with optimal texture and flavor.

Nutritional Profile and Health Benefits

Dehydration concentrates the nutritional components of pumpkin, creating a nutrient-dense food that retains most vitamins and minerals from the fresh vegetable. The process preserves beta-carotene, which the body converts to vitamin A, essential for eye health, immune function, and skin integrity. Dehydrated pumpkin strips also contain significant amounts of fiber, potassium, vitamin C, and various antioxidants including lutein and zeaxanthin.

- High concentration of beta-carotene supporting vision health and immune system function

- Rich dietary fiber content promoting digestive health and satiety

- Low calorie density making them suitable for weight management strategies

- Potassium content supporting cardiovascular health and blood pressure regulation

- Antioxidant compounds protecting cells from oxidative stress and inflammation

- Extended shelf life reducing food waste and ensuring year-round nutrient availability

Preparing Pumpkin for Dehydration

Proper preparation is essential for producing high-quality dehydrated pumpkin strips with consistent texture and flavor. Begin by selecting firm, mature pumpkins free from soft spots, mold, or damage. Wash the exterior thoroughly under running water, scrubbing away any dirt or debris with a vegetable brush. Cut the pumpkin in half using a sharp, heavy knife, then scoop out all seeds and stringy pulp from the cavity using a large spoon or ice cream scoop.

The next step involves removing the tough outer rind, which does not dehydrate well and creates an unpleasant texture in the finished product. Use a sharp vegetable peeler or paring knife to remove the rind completely, working in sections for better control. Once peeled, cut the pumpkin flesh into uniform strips approximately one-quarter to one-half inch thick and two to four inches long. Consistent sizing ensures even dehydration, preventing some pieces from over-drying while others remain too moist.

Pre-Treatment Options

Pre-treating pumpkin strips before dehydration can enhance color retention, improve texture, and extend shelf life. Blanching involves briefly immersing the strips in boiling water for two to three minutes, then immediately transferring them to ice water to halt the cooking process. This treatment deactivates enzymes that cause browning and nutrient degradation during storage. However, blanching also leaches some water-soluble nutrients and can create a slightly softer final texture.

Alternative pre-treatments include dipping strips in lemon juice or ascorbic acid solution, which prevents oxidation and browning while adding a subtle tartness that balances the pumpkin's natural sweetness. Some dehydrators prefer seasoning the strips before drying, applying cinnamon, nutmeg, ginger, or savory spices like garlic powder and paprika. These seasonings adhere well to the moist pumpkin surface and intensify during dehydration, creating flavored strips suitable for specific culinary applications.

Dehydration Methods and Techniques

Electric food dehydrators provide the most consistent and reliable results for creating dehydrated pumpkin strips. These appliances maintain steady temperatures between 125 and 135 degrees Fahrenheit while circulating air evenly across all trays. Arrange pumpkin strips in a single layer on dehydrator trays, leaving small gaps between pieces to allow air circulation. Avoid overlapping strips, as this creates uneven drying and potentially allows moisture pockets that can lead to spoilage.

Dehydration time varies based on strip thickness, pumpkin moisture content, ambient humidity, and dehydrator efficiency. Typical drying times range from eight to fourteen hours at 135 degrees Fahrenheit. Check the strips periodically after the eight-hour mark, testing for doneness by allowing a piece to cool completely then attempting to bend it. Properly dehydrated strips should be leathery and pliable or crisp and brittle depending on your preference, with no moisture beading when squeezed.

Oven Dehydration Process

Conventional ovens can dehydrate pumpkin strips when food dehydrators are unavailable, though temperature control proves more challenging. Set the oven to its lowest temperature setting, ideally between 140 and 170 degrees Fahrenheit. Arrange strips on baking sheets lined with parchment paper or silicone mats, spacing them apart for air circulation. Prop the oven door open slightly using a wooden spoon to allow moisture to escape and prevent temperature buildup.

Oven dehydration requires more attention than using a dedicated dehydrator, with strips needing rotation and flipping every two to three hours for even drying. The process typically takes six to twelve hours depending on oven temperature and strip thickness. Monitor closely to prevent over-browning or burning, particularly if your oven runs hot or has uneven heating patterns. While less energy-efficient than dehydrators, ovens provide a viable alternative for occasional small-batch production.

Sun Drying Considerations

Sun drying represents the most traditional dehydration method but requires specific weather conditions and carries higher contamination risks. This technique works best in hot, dry climates with consistent temperatures above 85 degrees Fahrenheit and relative humidity below twenty percent. Arrange pumpkin strips on clean screens or trays, covering them with cheesecloth to protect against insects while allowing air circulation. The process takes two to four days with strips brought indoors each evening to prevent moisture reabsorption from dew.

| Dehydration Method | Temperature | Time Required | Best For |

| Electric Dehydrator | 125-135°F | 8-14 hours | Consistent results, large batches |

| Conventional Oven | 140-170°F | 6-12 hours | Small batches, no equipment |

| Sun Drying | 85°F+ ambient | 2-4 days | Traditional method, no energy cost |

| Air Fryer | 120-140°F | 4-8 hours | Very small batches, testing |

Storage Methods and Shelf Life

Proper storage is critical for maintaining the quality and safety of dehydrated pumpkin strips over extended periods. Before packaging, allow the strips to cool completely to room temperature, preventing condensation that could introduce moisture into storage containers. Condition the dried strips by placing them in a large jar or container for seven to ten days, shaking daily to redistribute any remaining moisture evenly. If condensation appears inside the container during conditioning, return the strips to the dehydrator for additional drying time.

Store fully dried and conditioned pumpkin strips in airtight containers such as glass jars with tight-fitting lids, vacuum-sealed bags, or food-grade plastic containers with secure seals. Remove as much air as possible before sealing to minimize oxidation that degrades color, flavor, and nutrients. Label containers with the contents and date of dehydration for inventory management. Keep stored strips in a cool, dark, dry location away from direct sunlight, heat sources, and humidity.

Expected Shelf Life Under Various Conditions

Storage conditions dramatically impact how long dehydrated pumpkin strips maintain optimal quality. At room temperature in properly sealed containers, expect six to twelve months of quality storage. Refrigeration extends this period to twelve to eighteen months, while freezer storage can preserve the strips for two to three years with minimal quality loss. Vacuum sealing significantly improves shelf life by eliminating oxygen exposure, potentially doubling storage duration at any temperature.

- Room temperature storage (60-75°F): 6-12 months in airtight containers

- Refrigerated storage (35-40°F): 12-18 months with proper sealing

- Freezer storage (0°F or below): 24-36 months maintaining quality

- Vacuum-sealed room temperature: 12-24 months without refrigeration

- Oxygen absorber packets: Add 30-50% to expected shelf life in sealed containers

Rehydrating Dehydrated Pumpkin Strips

Rehydration restores moisture to dried pumpkin strips, making them suitable for cooking applications that require fresh or canned pumpkin. The basic rehydration method involves covering the strips with hot water and allowing them to soak for twenty to forty minutes until they reach the desired tenderness. The water-to-pumpkin ratio typically runs about three cups of water per one cup of dried strips, though exact amounts vary based on how thoroughly the strips were dehydrated and the intended final use.

For richer flavor, substitute vegetable broth, apple juice, or other liquids for plain water during rehydration. The pumpkin absorbs flavors from the rehydration liquid, enhancing the taste profile for specific recipes. Save the rehydration liquid after soaking, as it contains dissolved nutrients and pumpkin flavor perfect for adding to soups, sauces, or smoothies. Once rehydrated, the pumpkin can be pureed for pie filling, chopped for soups and stews, or used in any recipe calling for cooked fresh pumpkin.

Quick Rehydration Techniques

When time is limited, accelerated rehydration methods can restore pumpkin strips to usable condition in minutes rather than the standard thirty to forty-minute soak. Simmering the strips in hot liquid for ten to fifteen minutes achieves rapid rehydration while simultaneously cooking the pumpkin. This method works particularly well when the rehydrated pumpkin will be mashed or pureed, as the texture difference between quick and slow rehydration becomes negligible after processing.

Microwave rehydration offers another fast option by placing strips in a microwave-safe bowl with liquid, covering loosely, and heating in two-minute intervals until tender. Stir between intervals to ensure even moisture distribution. This method completes rehydration in six to ten minutes total but requires careful monitoring to prevent over-heating or uneven results. For recipes requiring firm texture, cold water rehydration over several hours or overnight in the refrigerator produces the best results with minimal mushiness.

Culinary Applications and Recipe Ideas

Dehydrated pumpkin strips serve diverse culinary purposes ranging from convenient snacking to ingredient substitution in traditional recipes. As a standalone snack, the strips provide a satisfying crunch when fully dried or a chewy texture when dried to a leathery consistency. Season them with cinnamon and sugar for a sweet treat, or apply savory seasonings like chili powder, cumin, and sea salt for a nutritious alternative to potato chips. The concentrated pumpkin flavor makes these strips particularly appealing to those seeking whole-food snacks without added sugars or preservatives.

In cooking applications, rehydrated pumpkin strips substitute directly for fresh or canned pumpkin in most recipes. Use them in pumpkin pie, pumpkin bread, muffins, pancakes, and other baked goods by rehydrating and pureeing to the consistency specified in the recipe. The strips work exceptionally well in soups and stews, where they can be added directly without pre-rehydration, absorbing liquid from the dish as it cooks. Their concentrated flavor means you may need slightly less volume compared to fresh pumpkin to achieve the same taste intensity.

Creative Uses Beyond Traditional Recipes

- Grind dried strips into pumpkin powder for adding to smoothies, oatmeal, or yogurt

- Steep strips in hot water to create pumpkin-infused tea with warming spices

- Add to homemade trail mix combining dried fruits, nuts, and seeds

- Incorporate into granola or energy bar recipes for added nutrition and flavor

- Use as a natural food coloring and flavoring agent in pasta dough or bread

- Create pumpkin-flavored seasonings by grinding with complementary spices

- Add to pet treat recipes for dogs who enjoy pumpkin's digestive benefits

Troubleshooting Common Issues

Several problems can arise during the dehydration process, but most have straightforward solutions. Uneven drying, where some strips remain moist while others become overly brittle, typically results from inconsistent sizing or inadequate air circulation. Ensure all strips are cut to uniform thickness and arrange them with spacing between pieces. Rotate trays periodically in stackable dehydrators to compensate for temperature variations between upper and lower levels.

Darkening or browning beyond the normal color intensification suggests excessive heat or prolonged exposure to air before dehydration. Lower the temperature slightly and ensure pre-treatment with lemon juice or ascorbic acid solution if color preservation is important. If strips develop an off odor or show signs of mold during storage, the dehydration was incomplete or storage conditions allowed moisture infiltration. Discard affected strips and evaluate both drying thoroughness and container seal quality for future batches.

Quality Assessment Indicators

| Quality Issue | Cause | Solution |

| Strips Too Hard/Brittle | Over-dehydration or high temperature | Reduce drying time or temperature |

| Strips Remain Moist | Insufficient drying time or thick cuts | Continue drying, cut thinner next time |

| Uneven Drying | Inconsistent sizing or poor air flow | Cut uniform pieces, rotate trays |

| Dark Brown Color | Oxidation or temperature too high | Pre-treat with lemon juice, lower heat |

| Mold During Storage | Incomplete drying or moisture exposure | Ensure thorough drying, improve sealing |

| Loss of Flavor | Extended storage or light exposure | Store in dark location, use within timeframe |

Cost-Effectiveness and Yield Calculations

Understanding the economics of producing dehydrated pumpkin strips helps determine whether home dehydration makes financial sense compared to purchasing commercially dried products or fresh pumpkin throughout the year. Fresh pumpkins during peak autumn season typically cost between fifty cents to two dollars per pound depending on variety and location. A ten-pound pumpkin yields approximately six to seven pounds of usable flesh after removing seeds, strings, and rind.

The dehydration process reduces weight by approximately ninety percent, meaning six pounds of fresh pumpkin flesh produces roughly nine to ten ounces of dried strips. When factoring in electricity costs for dehydrator operation, typically twenty to fifty cents per batch depending on local utility rates and equipment efficiency, homemade dehydrated pumpkin costs approximately three to six dollars per pound. This compares favorably to commercial dried pumpkin products that often retail for twelve to twenty dollars per pound, though the quality and flavor of homemade versions typically exceed mass-produced alternatives.

Maximizing Production Efficiency

- Purchase pumpkins during peak season when prices are lowest for maximum savings

- Process large batches to maximize dehydrator efficiency and minimize per-pound energy costs

- Grow your own pumpkins if space allows, reducing raw material costs to essentially zero

- Utilize every part of the pumpkin by roasting seeds separately and saving pulp for composting

- Share dehydrator time with neighbors or friends to split equipment and energy costs

- Consider solar dehydration in appropriate climates to eliminate electricity expenses entirely

Safety Considerations and Best Practices

Food safety must remain paramount throughout the dehydration and storage process to prevent foodborne illness and ensure product quality. Always work with clean equipment, utensils, and hands when preparing pumpkin for dehydration. Sanitize cutting boards, knives, and dehydrator trays with hot soapy water or mild bleach solution before use. Select only fresh, unblemished pumpkins free from mold, soft spots, or signs of decay, as contaminated raw materials can introduce pathogens that survive the dehydration process.

Temperature control during dehydration is critical for both safety and quality. Maintain dehydrator temperatures at or above 135 degrees Fahrenheit to inhibit bacterial growth while preventing temperatures from exceeding 145 degrees, which can cause surface hardening that traps moisture inside. This moisture trapping creates ideal conditions for microbial growth during storage. Test strips for complete dryness before storage, ensuring no moisture remains that could support mold or bacterial proliferation.

Identifying Spoilage and When to Discard

Regular inspection of stored dehydrated pumpkin strips helps identify spoilage before consumption. Visual indicators of spoilage include visible mold growth appearing as fuzzy white, green, or black spots on the strips. Any off odors, including musty, sour, or fermented smells, indicate microbial activity and require immediate discarding of the entire batch. Texture changes such as excessive stickiness or moisture when the strips should be dry also signal compromised storage conditions and potential spoilage.

- Visible mold growth of any color requires discarding the entire container contents

- Off odors including musty, sour, or fermented smells indicate spoilage

- Unexpected moisture or stickiness when strips should be dry signals storage failure

- Insects or insect eggs visible in storage containers require immediate disposal

- Discoloration beyond normal darkening suggests oxidation or contamination

- When in doubt about safety, discard questionable strips rather than risk illness

Comparing Homemade Versus Commercial Products

Commercial dehydrated pumpkin products offer convenience and consistent quality but often command premium prices and may contain additives not present in homemade versions. Manufactured dried pumpkin typically undergoes industrial dehydration using specialized equipment that achieves very uniform results and extremely low moisture content for extended shelf life. However, commercial products sometimes include preservatives, anti-caking agents, or sulfites to enhance color retention and prevent clumping, which some consumers prefer to avoid.

Homemade dehydrated pumpkin strips provide complete control over ingredient quality, allowing selection of organic or locally-grown pumpkins and elimination of all additives. The flavor profile often surpasses commercial products due to fresher raw materials and the ability to customize seasoning. However, home production requires time investment, equipment, and attention to detail throughout preparation, dehydration, and storage. The choice between homemade and commercial ultimately depends on individual priorities regarding cost, convenience, quality control, and dietary preferences.

Dehydrated pumpkin strips represent a practical, nutritious solution for preserving seasonal abundance while creating versatile ingredients suitable for year-round use. Mastering the preparation, dehydration, and storage techniques ensures consistent results that maximize nutritional retention and flavor quality. Whether you're seeking healthy snacks, convenient cooking ingredients, or an economical way to enjoy pumpkin beyond autumn's short season, properly dehydrated pumpkin strips deliver exceptional value and culinary flexibility. By understanding the complete process from pumpkin selection through final storage, you can confidently produce high-quality dehydrated pumpkin that enhances your cooking and provides wholesome nutrition throughout the year.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168