Content

- 1 Overview of Dehydrated Pumpkin Cube Drying Methods

- 2 Air Dried Dehydrated Pumpkin Cube Characteristics

- 3 Freeze Dried Dehydrated Pumpkin Cube Characteristics

- 4 Comparison of Physical and Functional Performance

- 5 Application Suitability in Food Formulations

- 6 Cost Efficiency and Supply Chain Considerations

- 7 Choosing the Right Dehydrated Pumpkin Cube Type

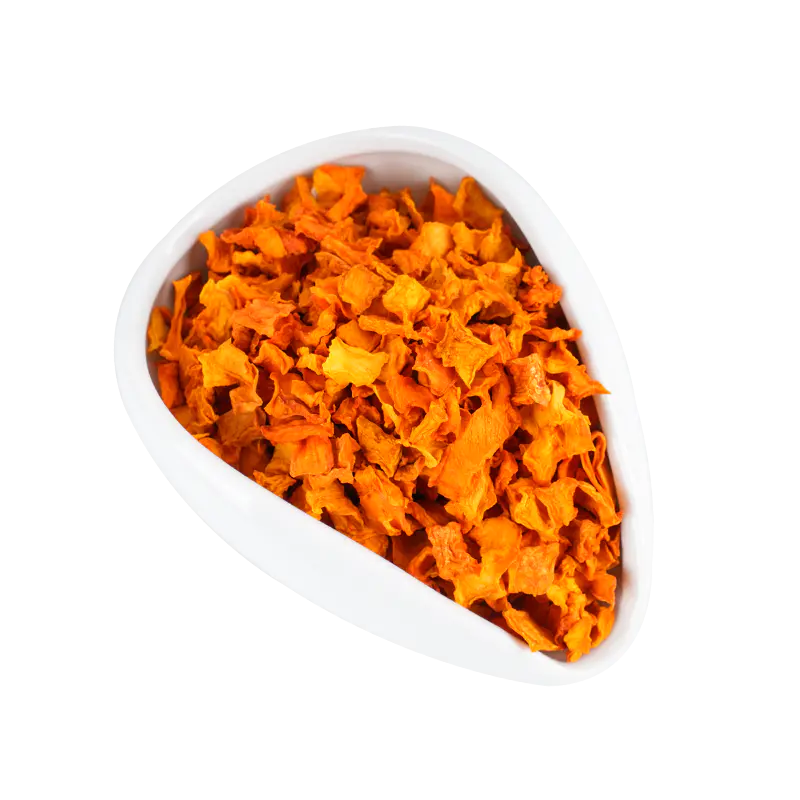

Overview of Dehydrated Pumpkin Cube Drying Methods

Dehydrated pumpkin cube is commonly produced using air drying or freeze drying, each method resulting in distinct physical and functional characteristics. The choice between air dried and freeze dried pumpkin cubes directly affects texture, color retention, rehydration behavior, cost structure, and suitability for specific food applications. Understanding these differences helps food manufacturers select the appropriate ingredient based on processing requirements and end product expectations.

Air Dried Dehydrated Pumpkin Cube Characteristics

Air dried dehydrated pumpkin cubes are produced by circulating hot air to gradually remove moisture from fresh pumpkin pieces. This method is widely used in industrial food processing due to its scalability and cost efficiency. The resulting cubes are dense, stable, and well suited for applications requiring controlled rehydration and structural integrity during cooking or baking.

Functional Properties of Air Dried Pumpkin Cube

- Firm texture that holds shape during extended thermal processing

- Gradual rehydration suitable for soups stews and baked products

- Lower production cost compared with freeze dried alternatives

Freeze Dried Dehydrated Pumpkin Cube Characteristics

Freeze dried pumpkin cubes are produced by freezing fresh pumpkin and removing moisture through sublimation under vacuum conditions. This process preserves the original cellular structure of the pumpkin, resulting in a porous and lightweight product. Freeze dried cubes are valued for rapid rehydration and high ingredient integrity in premium food applications.

Functional Properties of Freeze Dried Pumpkin Cube

- Highly porous structure enabling fast and uniform rehydration

- Lightweight texture suitable for instant and ready to eat foods

- Higher production cost due to complex processing requirements

Comparison of Physical and Functional Performance

Air dried and freeze dried pumpkin cubes differ significantly in density, moisture absorption rate, and processing tolerance. These differences influence how each type performs during formulation, cooking, and storage. Selecting the appropriate drying method depends on whether structural durability or rapid rehydration is prioritized.

|

Comparison Factor |

Air Dried Pumpkin Cube |

Freeze Dried Pumpkin Cube |

|

Density |

High and compact |

Low and porous |

|

Rehydration speed |

Moderate |

Rapid |

|

Texture after rehydration |

Firm with defined bite |

Soft and tender |

Application Suitability in Food Formulations

Air dried pumpkin cubes are commonly used in soups, bakery products, ready meals, and snack mixes where prolonged heating or baking occurs. Their ability to maintain structure under extended processing makes them suitable for industrial scale applications. Freeze dried pumpkin cubes are more often selected for instant foods, premium snack blends, and products where fast rehydration and minimal processing are required.

Typical Use Case Alignment

- Air dried cubes fit formulations requiring controlled moisture uptake

- Freeze dried cubes suit instant soups and lightweight dry blends

- Processing temperature tolerance differs between the two methods

Cost Efficiency and Supply Chain Considerations

From a commercial perspective, air dried dehydrated pumpkin cube offers advantages in production scalability, transportation efficiency, and storage stability. Freeze dried pumpkin cube, while offering superior rehydration performance, involves higher energy input and logistics cost. Manufacturers often balance these factors based on target market positioning and price sensitivity.

Choosing the Right Dehydrated Pumpkin Cube Type

Selecting between air dried and freeze dried dehydrated pumpkin cube requires alignment with product formulation goals, processing conditions, and cost targets. By understanding the functional differences created by each drying method, food manufacturers can make informed ingredient decisions that support consistent performance and product differentiation across diverse food categories.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168