Content

- 1 Functional Role of Dehydrated Pumpkin Cube in Bakery and Snack Products

- 2 Use of Dehydrated Pumpkin Cube in Bakery Applications

- 3 Application of Dehydrated Pumpkin Cube in Snack Formulations

- 4 Rehydration Behavior During Baking and Thermal Processing

- 5 Impact on Texture and Visual Appeal

- 6 Formulation Stability and Shelf Life Considerations

- 7 Product Differentiation in Bakery and Snack Categories

Functional Role of Dehydrated Pumpkin Cube in Bakery and Snack Products

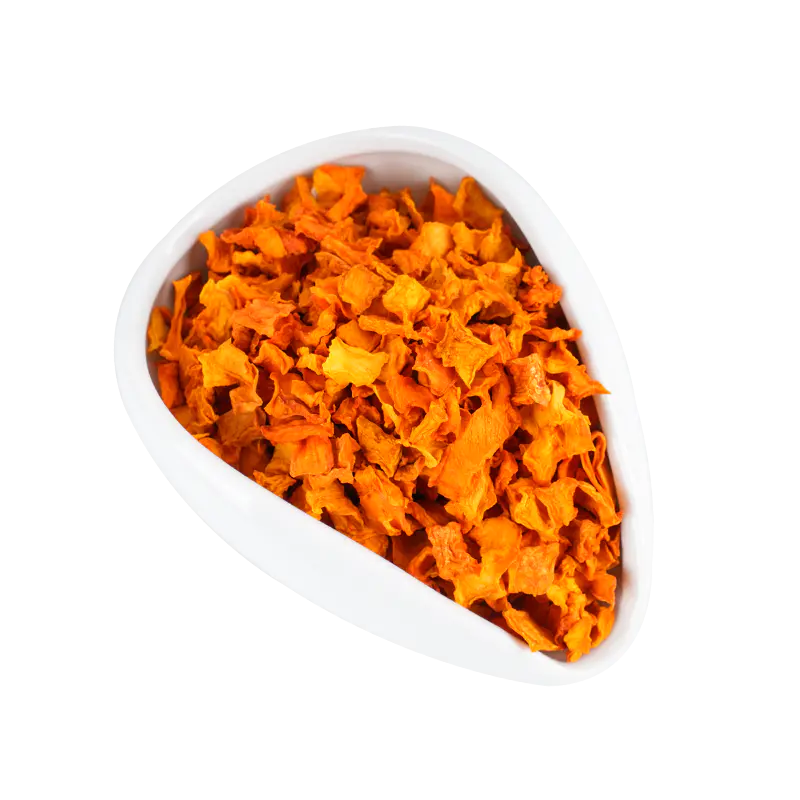

Dehydrated pumpkin cube is widely used in bakery and snack formulations as a stable vegetable ingredient that delivers texture, visual identity, and formulation flexibility. Produced by controlled dehydration and uniform cutting, the cubes retain pumpkin structure while offering extended shelf life and ease of handling. In baked and extruded snack systems, dehydrated pumpkin cube functions differently from powders or purees, making it suitable for products where visible inclusions or controlled rehydration are required.

Use of Dehydrated Pumpkin Cube in Bakery Applications

In bakery formulations, dehydrated pumpkin cube is commonly incorporated into breads, rolls, muffins, and specialty loaves. The cubes provide visible vegetable inclusions that remain distinguishable after baking, supporting product differentiation. When hydrated during dough mixing or baking, they soften while maintaining shape, contributing to a balanced internal structure without excessive moisture release.

Key Bakery Formulation Considerations

- Prehydration level affects cube softness and final crumb appearance

- Even distribution during mixing prevents localized moisture imbalance

- Moderate cube size supports uniform baking and visual consistency

Application of Dehydrated Pumpkin Cube in Snack Formulations

Snack manufacturers use dehydrated pumpkin cube in products such as baked snacks, cereal clusters, trail mixes, and vegetable based snack blends. In these systems, the cubes act as identifiable vegetable components that enhance texture variation. Their low moisture content allows integration into dry blends without compromising product stability.

Snack Processing Advantages

- Maintains structure during baking or light roasting

- Provides textural contrast in multi component snack systems

- Compatible with both sweet and savory seasoning profiles

Rehydration Behavior During Baking and Thermal Processing

The rehydration behavior of dehydrated pumpkin cube is a critical factor in bakery and snack formulations. During baking, steam and internal moisture gradually rehydrate the cubes, softening their texture without dissolving the structure. This controlled rehydration allows the cubes to integrate into the product matrix while remaining visually identifiable.

|

Application Type |

Hydration Source |

Resulting Texture |

|

Bread and rolls |

Dough moisture and baking steam |

Soft inclusions within crumb |

|

Baked snacks |

Surface moisture and heat |

Tender interior with light chew |

Impact on Texture and Visual Appeal

Dehydrated pumpkin cube enhances product appearance by introducing visible orange inclusions that contrast with surrounding dough or snack bases. This visual effect supports premium positioning and clean ingredient labeling. Texturally, the cubes create variation that differentiates products from uniform crumb or base structures, improving sensory perception without altering core formulation ratios.

Formulation Stability and Shelf Life Considerations

Due to its low moisture content, dehydrated pumpkin cube contributes minimal water activity to finished bakery and snack products. This characteristic supports shelf stability when combined with appropriate packaging and processing controls. Uniform drying and consistent cube sizing help reduce variability between batches, making the ingredient suitable for scaled commercial production.

Product Differentiation in Bakery and Snack Categories

In competitive bakery and snack markets, dehydrated pumpkin cube allows manufacturers to introduce visible vegetable content without complex processing changes. Its functional behavior during baking and its compatibility with dry and semi moist systems make it a practical ingredient for product innovation. When applied with controlled hydration and distribution, it delivers consistent performance across a wide range of bakery and snack formulations.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168