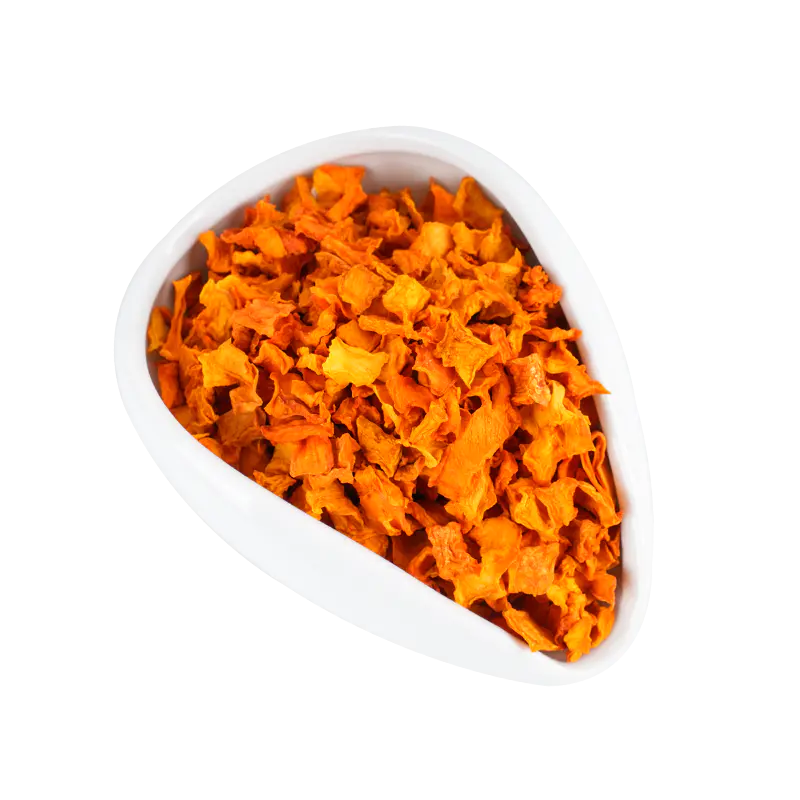

Dried purple sweet potato has emerged as a nutritional powerhouse and versatile ingredient, combining the natural health benefits of purple sweet potatoes with the convenience and extended shelf life of dehydrated foods. This vibrant purple tuber, known for its rich anthocyanin content and distinctive color, transforms into a concentrated source of nutrients and antioxidants through the drying process. Whether consumed as a healthy snack, incorporated into recipes, or ground into powder for various applications, dried purple sweet potato offers exceptional nutritional value while maintaining the unique flavor profile that distinguishes it from conventional orange sweet potatoes.

Content

- 1 Understanding Purple Sweet Potato Characteristics

- 2 Selecting and Preparing Purple Sweet Potatoes for Drying

- 3 Dehydration Methods and Techniques

- 4 Storage Methods and Shelf Life Optimization

- 5 Rehydration Techniques and Applications

- 6 Culinary Applications and Recipe Ideas

- 7 Making Purple Sweet Potato Powder

- 8 Quality Assessment and Troubleshooting

- 9 Commercial Versus Homemade Comparison

- 10 Health Benefits and Nutritional Science

- 11 Sustainable Production and Environmental Considerations

Understanding Purple Sweet Potato Characteristics

Purple sweet potatoes, scientifically known as Ipomoea batatas, differ fundamentally from their orange counterparts through their deep purple flesh that ranges from lavender to almost black depending on the variety. This distinctive coloration stems from high concentrations of anthocyanins, the same powerful antioxidants found in blueberries, blackberries, and red cabbage. The most common varieties include Stokes Purple, Okinawan sweet potato, and Ube from the Philippines, each offering slightly different flavor profiles and nutritional compositions.

The flesh of purple sweet potatoes contains a natural sweetness that intensifies during the drying process as sugars concentrate. Unlike regular potatoes, sweet potatoes maintain their nutritional integrity better during dehydration, retaining most vitamins, minerals, and phytonutrients. The texture when fresh is dense and creamy, characteristics that translate to a chewy or crispy consistency when properly dried depending on thickness and drying method. This unique combination of color, flavor, and nutrition makes purple sweet potatoes ideal candidates for dehydration and long-term storage.

Nutritional Composition and Health Benefits

The nutritional profile of dried purple sweet potato surpasses many conventional snack foods and even other dried vegetables. The dehydration process concentrates nutrients, creating a calorie-dense food packed with essential vitamins, minerals, and bioactive compounds. Anthocyanins, the pigments responsible for the purple color, function as potent antioxidants that combat oxidative stress and inflammation throughout the body. Research indicates these compounds may support cardiovascular health, cognitive function, and blood sugar regulation.

- Exceptional anthocyanin content providing powerful antioxidant protection against cellular damage

- High dietary fiber supporting digestive health and promoting satiety

- Rich in beta-carotene and vitamin A supporting vision and immune function

- Significant vitamin C content preserved during proper dehydration techniques

- Potassium and manganese supporting cardiovascular and bone health

- Complex carbohydrates providing sustained energy release

- Low glycemic index helping maintain stable blood sugar levels

Selecting and Preparing Purple Sweet Potatoes for Drying

Choosing high-quality purple sweet potatoes forms the foundation for successful dehydration. Select firm tubers with smooth, unblemished skin free from soft spots, cuts, or signs of sprouting. The size of individual potatoes matters less than overall quality, though medium-sized specimens typically offer the best flesh-to-skin ratio and more uniform texture. Fresh purple sweet potatoes should feel heavy for their size, indicating good moisture content and dense flesh that will yield better dried products.

Preparation begins with thorough washing under running water, using a vegetable brush to remove all soil and debris from the skin. While some prefer to peel purple sweet potatoes before drying, the skin contains additional nutrients and fiber that contribute to the final product's nutritional value. If leaving skin on, ensure it's completely clean and free from any blemishes. For peeled preparation, use a sharp vegetable peeler or paring knife to remove the skin completely, working over a bowl to catch the vibrant purple flesh.

Cutting Techniques and Sizing Considerations

Uniform sizing is critical for achieving consistent drying results across all pieces. Cut purple sweet potatoes into slices, chips, or cubes depending on your intended use and personal preference. Slices should measure between one-eighth to one-quarter inch thick for optimal drying time and final texture. Thinner slices create crispy chips similar to potato chips, while slightly thicker pieces produce a chewier, more substantial snack. Use a mandoline slicer for perfectly uniform thickness, or practice careful knife skills with a sharp chef's knife.

For cube or chunk preparations, aim for half-inch to three-quarter-inch pieces that dry evenly while maintaining enough substance for cooking applications. Cutting sweet potatoes immediately before dehydration minimizes oxidation and color loss, though the purple pigments prove more stable than the orange beta-carotene in regular sweet potatoes. If you must prepare pieces in advance, submerge them in cold water with a squeeze of lemon juice to prevent browning, though this step is less critical for purple varieties than orange ones.

Pre-Treatment Options

Pre-treatment methods can enhance the final quality of dried purple sweet potato, though they remain optional for many applications. Blanching involves briefly cooking the cut pieces in boiling water for two to three minutes, then immediately plunging them into ice water to stop the cooking process. This technique deactivates enzymes that cause color and nutrient degradation during storage, though it also results in some water-soluble nutrient loss and can affect final texture.

Steam blanching offers a gentler alternative that preserves more nutrients while still providing enzyme deactivation benefits. Steam cut pieces for three to five minutes until slightly tender but not fully cooked. Some prefer to skip blanching entirely, particularly when drying at optimal temperatures, as the purple sweet potato's natural antioxidants provide some protection against oxidation. Seasoning before drying allows flavors to penetrate the pieces, creating savory or sweet variations depending on your culinary intentions.

Dehydration Methods and Techniques

Electric food dehydrators provide the most reliable and consistent results for drying purple sweet potatoes. Set the dehydrator temperature between 125 and 135 degrees Fahrenheit for optimal nutrient retention while ensuring adequate moisture removal. Arrange purple sweet potato pieces in a single layer on dehydrator trays, leaving space between each piece for air circulation. Avoid overcrowding, as this extends drying time and can result in uneven moisture removal that compromises storage stability.

Drying time varies considerably based on slice thickness, sweet potato moisture content, ambient humidity, and dehydrator efficiency. Thin chips may complete drying in six to ten hours, while thicker slices or chunks require twelve to eighteen hours or longer. Check progress periodically after the initial six hours, testing pieces for doneness by allowing them to cool completely before assessing texture. Properly dried pieces should be brittle and snap cleanly for chips, or leathery and pliable for chewier preparations, with no moisture beading when squeezed.

Oven Drying Alternative

Conventional ovens can successfully dehydrate purple sweet potatoes when dedicated equipment is unavailable, though temperature control requires more attention. Set the oven to its lowest temperature setting, ideally between 140 and 170 degrees Fahrenheit. Higher temperatures risk cooking the sweet potatoes rather than dehydrating them, creating different texture and storage characteristics. Arrange pieces on baking sheets lined with parchment paper or silicone mats, ensuring adequate spacing for air circulation.

Prop the oven door open slightly using a wooden spoon to allow moisture to escape and prevent heat buildup that could cook rather than dehydrate the sweet potatoes. This technique proves less energy-efficient than using a dehydrator but works adequately for small batches. Rotate baking sheets and flip pieces every two to three hours to promote even drying. Total oven drying time typically ranges from eight to sixteen hours depending on thickness and oven characteristics. Monitor closely to prevent over-browning or burning, particularly near the end of the drying cycle.

Air Drying and Sun Drying Considerations

Traditional air drying methods work in specific climates but carry higher risks of contamination and uneven results. Sun drying requires consistently hot, dry weather with temperatures above 85 degrees Fahrenheit and relative humidity below twenty percent. Arrange purple sweet potato pieces on clean screens or trays, covering them with cheesecloth to protect against insects while allowing air circulation. The process takes two to four days with pieces brought indoors each evening to prevent moisture reabsorption from dew.

| Drying Method | Temperature | Time Required | Best Application |

| Food Dehydrator | 125-135°F | 6-18 hours | Most consistent results, large batches |

| Conventional Oven | 140-170°F | 8-16 hours | Small batches, no equipment needed |

| Air Fryer | 120-140°F | 5-10 hours | Very small batches, testing recipes |

| Sun Drying | 85°F+ ambient | 2-4 days | Traditional method, suitable climates only |

Storage Methods and Shelf Life Optimization

Proper storage is essential for maintaining the quality, color, and nutritional value of dried purple sweet potato over extended periods. Before packaging, allow all pieces to cool completely to room temperature, preventing condensation that could introduce moisture into storage containers. Implement a conditioning period by placing dried pieces in a large jar for seven to ten days, shaking daily to redistribute any remaining moisture evenly among all pieces. If condensation appears inside the container during conditioning, return the entire batch to the dehydrator for additional drying time.

Store fully dried and conditioned purple sweet potato pieces in airtight containers such as glass jars with tight-fitting lids, vacuum-sealed bags, or food-grade plastic containers with secure seals. The vibrant purple color proves sensitive to light exposure, which can cause fading over time, so opaque containers or storage in dark locations preserves the appealing appearance. Remove as much air as possible before sealing to minimize oxidation that degrades both color and nutritional content. Label all containers with contents and date for effective inventory management.

Expected Shelf Life Under Various Conditions

Storage conditions dramatically impact how long dried purple sweet potato maintains optimal quality. At room temperature in properly sealed containers kept in cool, dark locations, expect six to twelve months of quality storage. Refrigeration extends this period to twelve to twenty-four months, particularly beneficial in humid climates where room temperature storage proves challenging. Freezer storage can preserve dried purple sweet potato for two to three years with minimal quality degradation, though some texture changes may occur upon thawing.

- Room temperature storage (60-70°F, dark location): 6-12 months in airtight containers

- Refrigerated storage (35-40°F): 12-24 months with proper sealing

- Freezer storage (0°F or below): 24-36 months maintaining quality

- Vacuum-sealed room temperature: 12-18 months without refrigeration

- Oxygen absorber packets: Extend shelf life by 30-50% in sealed containers

- Mylar bags with oxygen absorbers: 2-5 years in cool, dark storage

Rehydration Techniques and Applications

Rehydrating dried purple sweet potato restores moisture content, making the pieces suitable for cooking applications that require the texture of fresh or cooked sweet potatoes. The basic rehydration method involves covering dried pieces with hot water and allowing them to soak for twenty to forty minutes until they reach desired tenderness. The water-to-sweet-potato ratio typically runs about three to four cups of liquid per one cup of dried pieces, though exact amounts vary based on drying thoroughness and intended use.

For enhanced flavor, substitute vegetable broth, coconut milk, or fruit juice for plain water during rehydration. The purple sweet potato absorbs flavors from the rehydration liquid, creating opportunities for creative seasoning. Reserve the rehydration liquid after soaking, as it contains dissolved nutrients and vibrant purple pigments perfect for adding color and nutrition to soups, smoothies, or baked goods. Once rehydrated, the sweet potato can be mashed for various applications, cubed for addition to dishes, or pureed for use in recipes requiring sweet potato puree.

Direct Cooking Methods

Many recipes allow adding dried purple sweet potato directly without pre-rehydration, particularly soups, stews, and braised dishes with sufficient cooking liquid. Add dried pieces to the pot early in the cooking process, allowing them to rehydrate gradually as the dish simmers. This method integrates the sweet potato seamlessly while infusing the cooking liquid with its distinctive color and subtle sweetness. Adjust liquid quantities in recipes to account for absorption by the dried sweet potato, typically adding an extra half to one cup of liquid per cup of dried pieces.

Culinary Applications and Recipe Ideas

Dried purple sweet potato serves diverse culinary purposes ranging from healthy snacking to ingredient substitution in both sweet and savory recipes. As a standalone snack, crispy chips provide satisfying crunch with natural sweetness and no added oils or preservatives when prepared without pre-treatment seasonings. Season them with sea salt for a savory option, cinnamon and coconut sugar for sweet treats, or creative spice blends like curry powder, chili-lime, or everything bagel seasoning for unique flavor profiles.

In baking applications, rehydrated and pureed purple sweet potato substitutes directly for regular sweet potato or pumpkin puree in muffins, breads, cakes, and pies. The vibrant purple color creates visually stunning baked goods, though it may shift toward blue or gray when combined with alkaline ingredients like baking soda. Adding a small amount of acid such as lemon juice or cream of tartar helps stabilize the purple hue. The natural sweetness means you can often reduce added sugar in recipes by twenty to thirty percent without compromising flavor.

Creative Culinary Applications

- Grind into fine powder for adding to smoothies, lattes, or oatmeal as a nutritional boost

- Create naturally purple pasta dough by incorporating purple sweet potato powder into the flour mixture

- Add to homemade granola or trail mix for color, nutrition, and natural sweetness

- Incorporate into energy balls or protein bars for sustained energy and antioxidant benefits

- Use as natural food coloring in frostings, icings, and dessert decorations

- Rehydrate and add to breakfast hash, grain bowls, or Buddha bowls for nutritional enhancement

- Blend into hummus or bean dips for unique color and subtle sweetness

- Create purple sweet potato chips as garnish for soups, salads, or main dishes

Making Purple Sweet Potato Powder

Transforming dried purple sweet potato pieces into fine powder expands their versatility and creates a convenient ingredient for numerous applications. Ensure pieces are completely dry and crispy before grinding, as any remaining moisture will create clumping and reduce powder shelf life. Use a high-powered blender, food processor, or dedicated spice grinder to pulverize the dried pieces into powder. Work in small batches for more consistent results, processing until the texture resembles fine flour or cocoa powder.

For the finest texture, sift the ground powder through a fine-mesh strainer, then re-grind any larger particles that don't pass through. The resulting powder should feel soft and uniform with no gritty pieces remaining. Store purple sweet potato powder in airtight containers in cool, dark locations to preserve color and prevent clumping. The powder form proves exceptionally convenient for adding to beverages, baked goods, and recipes where the texture of rehydrated pieces would be undesirable.

Powder Applications and Usage Rates

Purple sweet potato powder serves as both a nutritional supplement and natural food coloring. Start with small amounts when experimenting, typically one to two tablespoons per recipe, as the concentrated nature means a little powder provides substantial color and flavor. In smoothies, blend one to two tablespoons with other ingredients for nutrition and gorgeous purple color. For baking, substitute up to twenty-five percent of flour with purple sweet potato powder for nutritional enhancement and color, though this may affect texture and require slight adjustments to liquid ratios.

| Application | Typical Amount | Purpose |

| Smoothies | 1-2 tablespoons | Nutrition, color, mild sweetness |

| Baked Goods | 2-4 tablespoons per cup flour | Color, moisture, nutrition |

| Lattes & Beverages | 1-2 teaspoons | Flavor, color, antioxidants |

| Oatmeal & Porridge | 1-2 tablespoons | Nutrition, color, natural sweetness |

| Frosting & Icing | 2-3 tablespoons | Natural purple coloring |

| Pasta Dough | 3-4 tablespoons per 2 cups flour | Color, nutrition, unique flavor |

Quality Assessment and Troubleshooting

Evaluating the quality of dried purple sweet potato involves assessing color, texture, moisture content, and flavor. Properly dried pieces maintain vibrant purple coloring, though some darkening compared to fresh sweet potato is normal due to natural concentration during dehydration. Excessive browning or color fading to gray suggests over-exposure to light, excessive heat during drying, or oxidation from improper storage. The texture should be uniformly crisp for chips or consistently leathery for chewy preparations, with no soft or moist spots indicating incomplete drying.

Common issues during the drying process include uneven dehydration, color changes, and texture problems. Uneven drying where some pieces remain moist while others become overly brittle typically results from inconsistent sizing or inadequate air circulation. Ensure all pieces are cut to uniform thickness and arrange them with spacing on dehydrator trays. Dark spots or excessive browning suggest temperature settings too high or prolonged drying times; reduce temperature and check pieces more frequently to prevent over-drying.

Identifying Spoilage and Storage Problems

Regular inspection of stored dried purple sweet potato helps identify potential spoilage before consumption. Visual indicators include visible mold growth appearing as fuzzy white, green, or black spots on the pieces. Any off odors, including musty, sour, or fermented smells, indicate microbial activity requiring immediate disposal of the entire batch. Unexpected moisture or stickiness when pieces should be dry signals storage container failure or exposure to humidity.

- Visible mold of any color requires discarding entire container contents immediately

- Off odors including musty, sour, or unusual smells indicate spoilage

- Unexpected moisture or softness suggests inadequate drying or storage failure

- Insects or insect eggs visible in containers require immediate disposal

- Excessive color fading to gray or brown indicates oxidation or light exposure

- Loss of characteristic sweet potato flavor suggests extended storage or degradation

Commercial Versus Homemade Comparison

Commercial dried purple sweet potato products offer convenience and consistent quality but typically command premium prices reflecting processing, packaging, and distribution costs. Manufactured products undergo industrial dehydration using specialized equipment that achieves extremely uniform results and very low moisture content for extended shelf life. However, commercial products may include additives such as preservatives, anti-caking agents, or oils to enhance texture and prevent clumping, which some consumers prefer to avoid for health or dietary reasons.

Homemade dried purple sweet potato provides complete control over ingredient quality, allowing selection of organic or locally-grown sweet potatoes and complete elimination of additives. The flavor profile often surpasses commercial products due to fresher raw materials and the ability to customize thickness, texture, and seasoning to personal preferences. However, home production requires time investment, equipment, and attention to detail throughout preparation, dehydration, and storage phases. The choice between homemade and commercial ultimately depends on individual priorities regarding cost, convenience, quality control, and dietary requirements.

Cost Analysis and Yield Expectations

Understanding the economics of producing dried purple sweet potato helps determine whether home dehydration makes financial sense compared to purchasing commercial products. Fresh purple sweet potatoes typically cost between two to four dollars per pound depending on variety, season, and location. A five-pound batch of fresh sweet potatoes yields approximately three to four pounds of usable flesh after peeling and trimming, which reduces to roughly eight to twelve ounces of dried product after moisture removal.

When factoring in electricity costs for dehydrator operation, typically thirty to sixty cents per batch depending on local utility rates and drying time, homemade dried purple sweet potato costs approximately eight to fifteen dollars per pound. This compares favorably to commercial dried purple sweet potato products that often retail for twenty to forty dollars per pound, though premium organic or specialty varieties can exceed fifty dollars per pound. The cost advantage of homemade production increases significantly when processing larger batches or sourcing sweet potatoes at bulk or seasonal prices.

Health Benefits and Nutritional Science

The health benefits of purple sweet potatoes stem primarily from their exceptional anthocyanin content, which remains largely intact through proper dehydration processes. These water-soluble pigments function as powerful antioxidants, neutralizing free radicals that contribute to cellular damage, inflammation, and chronic disease development. Research indicates that regular consumption of anthocyanin-rich foods may reduce cardiovascular disease risk, improve cognitive function, and support healthy aging through multiple biological mechanisms.

Beyond anthocyanins, dried purple sweet potato provides substantial dietary fiber supporting digestive health and promoting beneficial gut bacteria proliferation. The complex carbohydrates digest slowly, providing sustained energy release while minimizing blood sugar spikes compared to simple carbohydrates. This low glycemic response makes purple sweet potato suitable for individuals managing diabetes or seeking stable energy throughout the day. The concentrated nutrient profile includes significant amounts of potassium, manganese, vitamin C, and vitamin A precursors, all essential for various physiological functions.

Specific Health Applications

- Cardiovascular support through anthocyanins that improve blood vessel function and reduce inflammation

- Blood sugar regulation aided by fiber content and low glycemic index carbohydrates

- Digestive health promotion through prebiotic fiber feeding beneficial gut bacteria

- Eye health protection from vitamin A and antioxidant compounds lutein and zeaxanthin

- Immune function enhancement through vitamin C and beta-carotene content

- Anti-inflammatory effects potentially reducing chronic disease risk

- Weight management support through high satiety value and nutrient density

Sustainable Production and Environmental Considerations

Dehydrating purple sweet potatoes at home contributes to sustainable food practices by reducing food waste and preserving seasonal abundance for year-round use. Sweet potatoes that might otherwise spoil can be transformed into shelf-stable products requiring no refrigeration, conserving energy while extending usability. The process allows consumers to take advantage of seasonal price fluctuations, purchasing sweet potatoes when abundant and inexpensive for processing and storage during times of scarcity or higher prices.

Energy consumption represents the primary environmental consideration for home dehydration. Electric dehydrators typically consume between three hundred to one thousand watts depending on size and features, translating to approximately two to eight kilowatt-hours for a complete drying cycle. Solar dehydration eliminates electricity costs entirely while harnessing renewable energy, though this method requires appropriate climate conditions and more time. Regardless of method, home dehydration generally proves more environmentally friendly than purchasing commercial products when considering transportation, industrial processing, and packaging impacts.

Dried purple sweet potato represents an exceptional combination of nutrition, convenience, and culinary versatility. The dehydration process concentrates beneficial compounds while creating a shelf-stable product that retains most of the fresh sweet potato's valuable nutrients. Whether consumed as a healthy snack, incorporated into recipes, or ground into powder for various applications, dried purple sweet potato delivers outstanding nutritional value and unique flavor. Understanding the complete process from sweet potato selection through final storage and utilization ensures consistent results that maximize both quality and health benefits. By mastering these techniques, you can enjoy the remarkable properties of purple sweet potatoes throughout the year while exploring creative culinary applications that showcase this vibrant, nutritious superfood.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168