Manufacturers across food and non-food sectors frequently choose dried potato ingredients — flakes, granules, flour, and dehydrated dices — instead of fresh potatoes. This choice is driven by measurable operational, functional, economic, and sustainability benefits. The sections below explain these advantages in practical terms and offer clear guidance for selecting and using dried potato products in production lines.

Content

- 1 Functional advantages: predictable performance and formulation control

- 2 Operational advantages: logistics, storage and handling

- 3 Economic advantages: cost predictability and supply resilience

- 4 Quality control and regulatory benefits

- 5 Formulation and processing flexibility

- 6 Packaging, storage and shelf-life advantages

- 7 Sustainability and environmental considerations

- 8 Nutritional and labeling trade-offs

- 9 Common pitfalls and practical mitigations

- 10 Implementation checklist for manufacturers

- 11 Conclusion: choosing dried potatoes intentionally

Functional advantages: predictable performance and formulation control

Dried potatoes provide consistent starch content, particle size, and water activity that make formulation outcomes repeatable. Unlike variable fresh tubers, dried inputs reduce batch-to-batch variation in viscosity, texture, color and expansion behavior during thermal processing.

Consistent starch and binder properties

Potato flakes and flour deliver known levels of native starch that act as thickeners, binders or humectants. This lets R&D set precise percentages for viscosity control in soups, sauces, extruded snacks, and pet food, and minimizes the need for on-the-fly corrections on the line.

Faster, controlled rehydration and thermal response

Instant flakes and granules rehydrate quickly and predictably with hot liquid, enabling tight process windows for mixing, forming, and frying operations. This predictability reduces rejects from under- or over-hydration and helps maintain texture targets across production runs.

Operational advantages: logistics, storage and handling

From a plant-floor perspective, dried potatoes simplify inventory management and reduce spoilage risks compared with fresh tubers that require cold storage and rapid turnover.

Reduced cold-chain dependence and simpler warehousing

Dried products are shelf-stable at ambient temperatures. Eliminating refrigerated storage lowers energy costs, frees cold-room capacity for other goods, and simplifies receiving and staging procedures.

Lower waste and fewer quality losses

Fresh potatoes are vulnerable to sprouting, rot and mechanical damage, generating trimming waste and variable yields. Dried materials arrive uniform and ready-to-use, reducing processing scrap and the labor required to sort or trim raw tubers.

Economic advantages: cost predictability and supply resilience

Using dried potatoes often improves cost forecasting and reduces exposure to seasonal price swings and logistic disruptions that affect fresh produce.

Stable unit costs and bulk purchasing

Dried ingredients can be bought in large, sealed bulk lots with long shelf life, allowing manufacturers to negotiate better prices and avoid frequent spot-market purchases required by fresh potato volatility.

Lower transportation costs per usable kilogram

Water constitutes most of fresh potato weight. Removing water reduces shipping weight and volume, cutting freight cost and CO₂ emissions per unit of functional ingredient delivered to the plant.

Quality control and regulatory benefits

Dried potato suppliers typically provide certificates of analysis for moisture, ash, microbiological status and particle size, which simplifies incoming QA checks and regulatory compliance for finished products.

Easier HACCP integration and microbiological control

Lower water activity in dried potatoes inhibits microbial growth, reducing immediate food-safety hazards at receiving and allowing more predictable cleaning and sanitation scheduling compared with handling large volumes of wet produce.

Formulation and processing flexibility

Dried potato derivatives enable innovations across product categories because they are available in multiple particle sizes and functional grades suited to specific processing methods.

|

Form |

Typical use |

Processing advantage |

|

Flakes / granules |

Instant mashed, soups, ready meals |

Fast rehydration, minimal pre-cooking. |

|

Potato flour |

Bakery, batter, binding |

Improves structure, replaces part of wheat flour. |

|

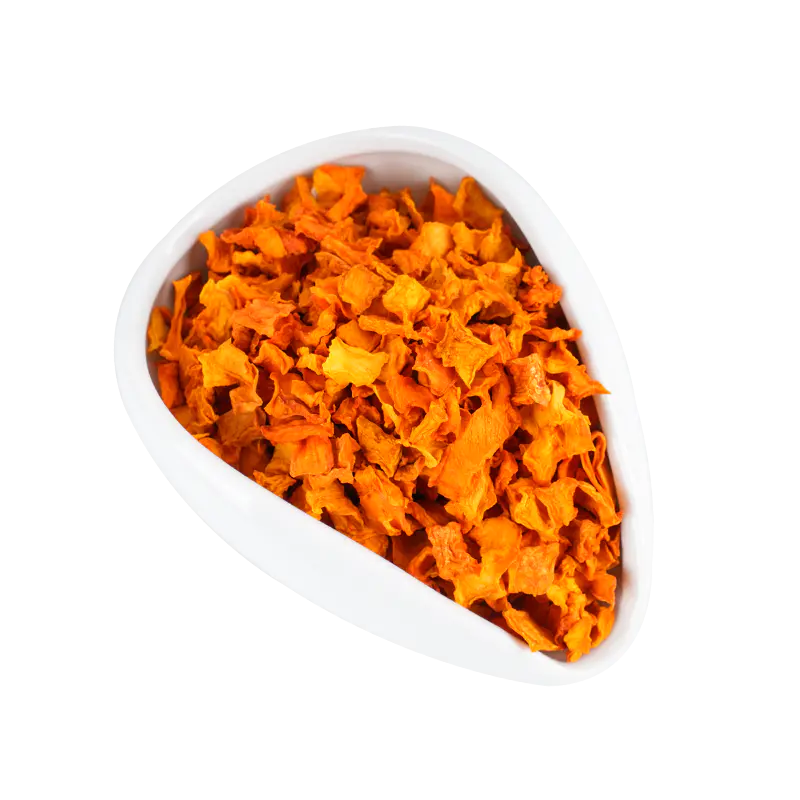

Dehydrated dices/slices |

Soups, stews, freeze-dry meals |

Ready particle form for inclusion without chopping. |

Packaging, storage and shelf-life advantages

Dried potatoes packaged with moisture and oxygen barriers maintain quality for months to years. This reduces inventory turnover frequency and supports just-in-time production without daily deliveries of perishables.

Sustainability and environmental considerations

Lower transportation weight and reduced cold-chain demands translate to smaller carbon footprints per functional unit. Additionally, less on-site food waste and trim from peeling and sorting reduce overall product loss across the value chain.

Nutritional and labeling trade-offs

Dehydration reduces some heat-sensitive nutrients such as vitamin C, but dried potatoes retain carbohydrates, fiber and minerals. Manufacturers must consider whether to fortify finished goods or adjust nutrition claims when replacing fresh potato content with dried equivalents.

Common pitfalls and practical mitigations

Switching to dried potatoes requires attention to hydration control, dust management, and ingredient blending to match sensory expectations. Below are frequent issues and solutions.

- Gummy or pasty final texture — lower hydration level or reduce high-temperature hold times; test incremental water changes at pilot scale.

- Flavor perceived as flat — use higher-grade culinary flakes, add potato juice concentrate or seasoning adjustments to match fresh flavor.

- Dust and inhalation risk during handling — enclose transfer points, use local extraction, and implement wetting or slurrying systems for bulk transfer.

- Labeling differences — verify regulatory language for “potato flour” or “potato flakes” in target markets and update nutritional panels for processed losses.

Implementation checklist for manufacturers

Before substituting or introducing dried potato ingredients, follow a short implementation checklist to reduce surprises on the production floor:

- Run lab-scale rehydration and sensory tests across candidate grades.

- Pilot process the chosen grade at scale to confirm equipment compatibility and cook/fry behavior.

- Update HACCP risk assessments and supplier certificates of analysis (COA) requirements.

- Adjust procurement contracts to include moisture, particle size, and shelf-life guarantees.

Conclusion: choosing dried potatoes intentionally

Dried potato ingredients offer practical, measurable advantages over fresh tubers for many manufacturing scenarios: they provide formulation consistency, lower logistics and storage costs, easier quality control, and environmental benefits. Success depends on selecting the right form and grade, validating rehydration and processing parameters, and managing labeling and nutritional implications. When integrated thoughtfully, dried potatoes become an efficient, reliable building block for scalable production.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168