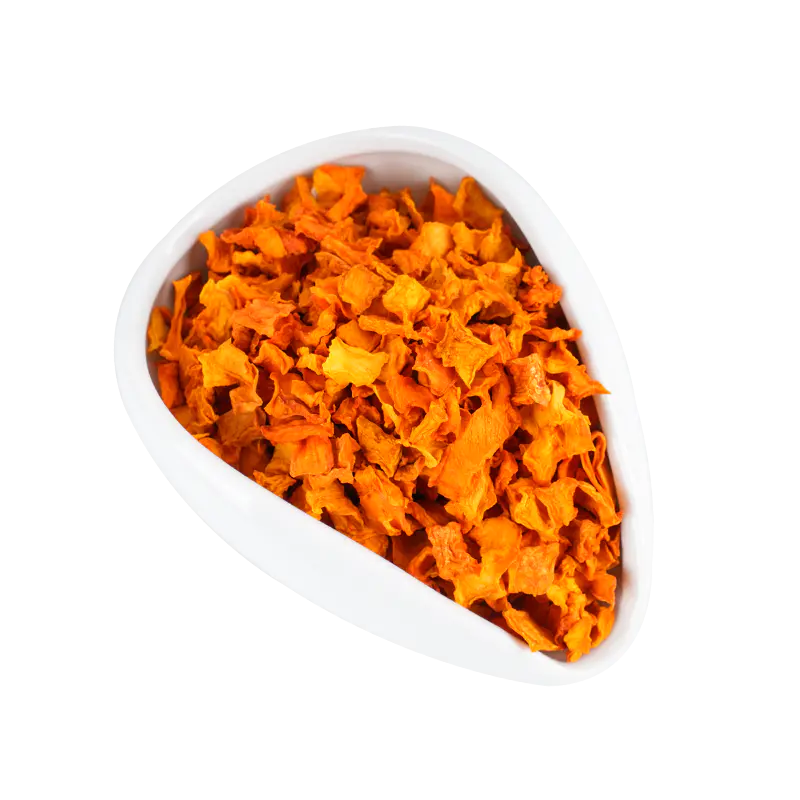

Dried potatoes appear in several commercial forms — flakes, granules (instant mashed), flour, and dehydrated slices or dices. Each form is produced by cooking, dehydration (drum drying, spray drying or air drying) and milling or cutting. The processing method determines texture, rehydration speed, and best uses. Understanding these forms helps match product to purpose, whether home cooking, foodservice, military rations, or industrial applications.

Content

- 1 Culinary uses in professional and home kitchens

- 2 Commercial and industrial applications

- 3 Rehydration and cooking tips (practical ratios and methods)

- 4 Quality grades and selecting the right product

- 5 Packaging, storage and shelf life

- 6 Nutritional and labeling considerations

- 7 Common pitfalls and troubleshooting

- 8 Conclusion: matching form to function

Culinary uses in professional and home kitchens

Dried potatoes are widely used where convenience, shelf life, and consistent performance matter. They save time and storage space while delivering potato flavor and texture when rehydrated properly.

Instant mashed and side dishes

Flakes and granules rehydrate quickly with hot water or milk and are the backbone of instant mashed potato mixes used in restaurants, cafeterias, and home kitchens. They provide consistent mouthfeel and are easy to portion and scale.

Ingredient in ready meals and convenience foods

Dried potatoes are incorporated into soups, sauces, shepherd’s pie fillings, frozen meals, and dehydrated camping meals. Their low moisture helps control product stability and texture during processing and frozen storage.

Breading, coating and snack manufacture

Potato flour and finely milled flakes are used in batters, coatings, and extruded snacks to improve crispness, provide color, and add binding. Their starch content contributes to expansion and texture in chips, crisps, and extruded snacks.

Commercial and industrial applications

Beyond direct food uses, dried potatoes supply starch and functional powders for multiple industries. Their dry, transportable form makes them attractive for large-scale food manufacturing and non-food uses.

Starch and binder applications

Dried potatoes are a source of native potato starch used as a thickener, binder, or adhesive in processed foods, paper products, and biodegradable packaging formulations.

Pet food and animal feed

Blends containing potato flakes or flour increase carbohydrate content, improve pellet binding, and add palatability in certain pet food and livestock feed formulations.

Emergency, military and humanitarian rations

Long shelf life and light weight make dried potatoes ideal for emergency food kits, field rations, and humanitarian food supplies where refrigeration and logistics are limited.

Rehydration and cooking tips (practical ratios and methods)

Correct rehydration restores desirable texture. Ratios vary by product and desired consistency; below are typical starting points and method notes you can adapt.

|

Product form |

Typical rehydration ratio (water:product) |

Notes |

|

Flakes (instant) |

1:1 to 1.25:1 by weight (hot liquid) |

Stirring with hot water/milk produces smooth mash quickly; adjust for creaminess. |

|

Granules |

1:1 by weight (hot liquid) |

Slightly coarser texture; good for rustic mashed styles. |

|

Potato flour |

Use to taste; typically 10–25% of flour weight in recipes |

Used as binder or thickener; requires hydration and usually heat to gelatinize starch. |

|

Dehydrated dices/slices |

2:1 to 3:1 water by volume (simmer until tender) |

Longer soak or simmer; great in soups and stews. |

Practical method: bring liquid to a boil, remove from heat, add flakes while stirring, cover 2–3 minutes, then stir to finish. For creamier results, rehydrate in warm milk or add butter and whisk.

Quality grades and selecting the right product

Producers offer multiple grades depending on intended use: culinary-grade (higher flavor, larger particles), industrial-grade (consistent starch content), and instant-grade (rapid rehydration). Consider these selection factors:

- Desired texture after rehydration (smooth vs. rustic)

- Processing needs (e.g., extrusion, baking, battering)

- Labeling needs (gluten-free claims, clean-label, native starch)

- Cost and supply stability for large-scale purchasing

Packaging, storage and shelf life

Dried potatoes are hygroscopic; they must be kept dry, cool, and sealed. Commercial packaging ranges from retail pouches to bulk kraft bags with moisture barriers. Typical shelf life is 12–24 months for properly stored product; industrial sealed packaging can extend this depending on oxygen and moisture control.

Nutritional and labeling considerations

Dried potatoes retain carbohydrates, some fiber, and minerals. Processing reduces vitamin C and some heat-sensitive nutrients. When formulating products, account for nutrient losses and adjust fortification if required. Labels should declare the form (potato flakes, potato flour), any allergens from processing, and storage instructions.

Common pitfalls and troubleshooting

Common issues include gummy texture from over-hydration, bland flavor when using low-grade flakes, and clumping if moisture enters the product. Solutions:

- Adjust water ratios and temperature; rehydrate gradually and whisk or fold to break lumps.

- Blend smaller batches of different grades to balance cost and flavor.

- Store in airtight containers with desiccant for long-term bulk storage.

Conclusion: matching form to function

Dried potatoes are versatile ingredients across culinary, commercial, and industrial domains. Choosing the correct form, mastering rehydration ratios, and following proper storage practices unlock their full value — from quick home meals to large-scale manufacturing and emergency rations.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168