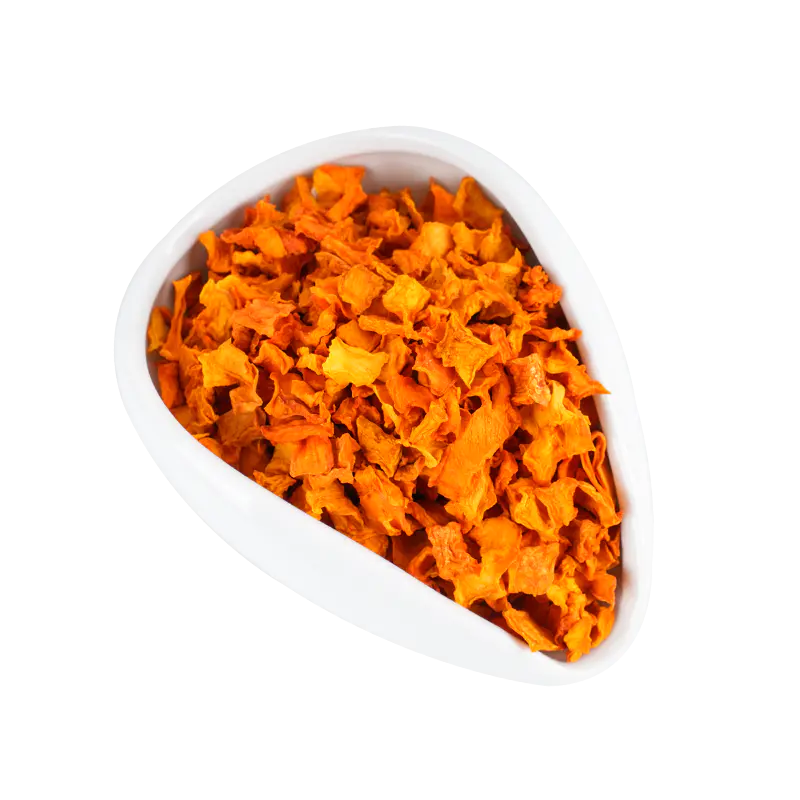

In recent years, the food industry has witnessed a growing demand for natural and clean-label ingredients. One product that has gained significant attention is dehydrated celery powder, which has become a widely accepted natural substitute for synthetic nitrites used in cured meat production. This shift reflects both regulatory trends and consumer preferences for more natural, minimally processed foods.

Dehydrated celery powder plays an important role in maintaining the color, flavor, and safety of cured meats—similar to conventional curing agents—while allowing manufacturers to label their products as “no added nitrites” or “naturally cured.” Understanding how this ingredient functions provides insight into its importance in modern meat processing.

Content

- 1 1. Natural Source of Nitrates

- 2 2. Preservation and Food Safety

- 3 3. Maintaining Color and Flavor

- 4 4. Clean-Label and “Natural” Marketing Advantage

- 5 5. Processing and Standardization Challenges

- 6 6. Nutritional and Sensory Benefits

- 7 7. Environmental and Sustainability Considerations

- 8 8. Future Market Outlook

- 9 Conclusion

1. Natural Source of Nitrates

The main reason dehydrated celery powder serves as a natural curing agent lies in its high nitrate content. Celery, especially when grown under specific conditions, naturally accumulates nitrates in its stalks and leaves. During processing, celery is cleaned, chopped, and dehydrated under controlled temperatures to preserve these naturally occurring nitrates. The result is a concentrated powder rich in nitrate compounds.

However, nitrates themselves are not directly responsible for meat preservation. They must be converted into nitrites through a bacterial or enzymatic process. In natural curing systems, this conversion is typically facilitated by starter cultures such as Staphylococcus carnosus or Micrococcus varians, which transform nitrates into nitrites during curing. The produced nitrites then perform the same preservative and color-fixing functions as synthetic sodium nitrite.

2. Preservation and Food Safety

In cured meats, nitrites play a crucial role in inhibiting the growth of harmful microorganisms, especially Clostridium botulinum, which causes botulism. They also slow down the oxidation of fats, which prevents rancidity and extends shelf life.

When dehydrated celery powder is used, the naturally derived nitrites perform these same protective actions. This ensures that the product remains microbiologically safe while retaining its characteristic cured flavor.

Consumers often perceive “naturally cured” products as safer and healthier, even though the functional nitrite levels are similar to those in traditionally cured meats. The key difference lies in the source—plant-based nitrates versus synthetic chemical additives.

3. Maintaining Color and Flavor

A major visual and sensory appeal of cured meats like bacon, ham, and sausages comes from their pink or red color and distinctive cured flavor. Nitrites react with myoglobin in the meat to form nitric oxide myoglobin, the pigment responsible for that familiar cured appearance.

Dehydrated celery powder, once converted to nitrite through microbial action, supports this same reaction naturally. The end result is a visually appealing, flavorful cured product that meets consumer expectations—without the direct addition of synthetic curing salts.

4. Clean-Label and “Natural” Marketing Advantage

Today’s consumers are increasingly attentive to ingredient lists and are wary of chemical-sounding additives. Phrases such as “no artificial preservatives,” “naturally cured,” or “clean label” have become powerful marketing tools.

By replacing synthetic nitrites with dehydrated celery powder, manufacturers can produce cured meats labeled as “uncured” or “naturally cured using celery powder and sea salt.” This appeals to health-conscious consumers seeking transparency and natural alternatives.

From a regulatory standpoint, many food authorities classify celery powder as a natural ingredient, not as a direct additive, giving it a labeling advantage even though it performs the same technical functions as sodium nitrite.

5. Processing and Standardization Challenges

While dehydrated celery powder offers clear advantages, it also presents challenges in production consistency. The nitrate concentration in celery can vary depending on the plant variety, growing conditions, soil type, and harvest time.

To achieve predictable curing results, manufacturers often use standardized celery powders, where nitrate levels are measured and adjusted before use. This ensures consistent curing performance and food safety across production batches.

Additionally, because the natural conversion from nitrate to nitrite depends on microbial activity, curing with celery powder typically requires longer processing times and controlled fermentation conditions compared to direct nitrite addition.

6. Nutritional and Sensory Benefits

Beyond its curing role, dehydrated celery powder adds subtle nutritional and sensory advantages. It contains small amounts of vitamins, minerals, and antioxidants such as vitamin K, potassium, and flavonoids, which can contribute to overall product quality.

Its mild herbal aroma and natural plant-based origin also appeal to consumers who associate celery powder with freshness and healthfulness.

7. Environmental and Sustainability Considerations

Using dehydrated celery powder aligns with the broader movement toward sustainable and plant-based food ingredients. By sourcing nitrates from vegetables rather than synthetic chemicals, manufacturers can reduce reliance on industrially produced additives. Furthermore, dehydrating celery allows for efficient use of surplus crops, helping reduce agricultural waste.

The processing of celery into powder form also minimizes transportation weight and extends shelf life, supporting sustainability goals across the supply chain.

8. Future Market Outlook

The global demand for natural curing agents continues to grow alongside the “clean label” food trend. Dehydrated celery powder is expected to see expanding applications beyond traditional meats, including in plant-based meats, ready-to-eat meals, and snack products that aim to maintain color and freshness naturally.

Advancements in agricultural control, nitrate standardization, and microbial fermentation are likely to enhance the efficiency and consistency of celery-based curing systems in the coming years.

Conclusion

Dehydrated celery powder represents a successful balance between food safety, sensory quality, and consumer preference. As a natural source of nitrates, it enables manufacturers to achieve the same preservation and curing effects as synthetic nitrites, while meeting growing market demand for clean-label and naturally processed foods.

Through precise processing, microbial conversion, and formulation control, dehydrated celery powder continues to redefine the standards of natural meat curing. Its dual role—as both a functional preservative and a marketing advantage—ensures its lasting relevance in the evolving global food industry.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168