Rehydration is a critical functional property of dried pumpkin, directly influencing its usability and sensory quality in various culinary applications such as soups, purees, baked goods, and snacks. Optimizing rehydration involves managing multiple aspects from raw material selection, drying methods, and pre-treatments, to post-drying handling and rehydration conditions. The goal is to produce dried pumpkin that, upon rehydration, meets the desired texture, flavor, and functional requirements for its intended use.

- Selection of Drying Technology and Parameters

The drying method and its parameters fundamentally impact the microstructure of the dried pumpkin and thus its ability to reabsorb water.

Freeze-drying (Lyophilization): This technique preserves the cellular structure by sublimating ice crystals directly from frozen pumpkin tissue under vacuum conditions. It results in a porous, highly porous matrix that rehydrates quickly and almost completely, closely resembling the fresh pumpkin’s texture and flavor. Freeze-dried pumpkin is ideal for applications requiring smooth purees, soups, or instant foods where rapid and complete rehydration is desirable. However, freeze-drying is energy-intensive and costly.

Hot Air Drying: Conventional hot air drying involves exposing sliced or diced pumpkin to heated air (typically 50–70°C). While economical and scalable, this method causes some shrinkage, cell wall collapse, and possibly Maillard browning, which reduce rehydration capacity and may yield a firmer or tougher texture upon rehydration. Hot air dried pumpkin suits applications where a firmer texture is acceptable or desired, such as dehydrated snacks or ingredient additions to baked products.

Vacuum Drying and Microwave Drying: These methods can offer intermediate benefits by combining gentle drying conditions with shorter drying times. Vacuum drying reduces oxidation and thermal damage, thus improving rehydration compared to hot air drying. Microwave drying accelerates moisture removal and can preserve better cell structure, but care is needed to avoid uneven drying.

Drying parameters such as temperature, relative humidity, and drying time must be optimized to minimize nutrient degradation and structural damage. Lower drying temperatures generally preserve rehydration better but increase processing time and costs.

- Pre-Treatment of Fresh Pumpkin

Pre-treatment of pumpkin prior to drying can enhance rehydration properties by modifying tissue characteristics:

Blanching: Brief heat treatment (steam or hot water) inactivates enzymes such as polyphenol oxidase that cause browning and texture degradation. Proper blanching softens cell walls and reduces microbial load, improving the rehydrated product’s appearance and texture.

Osmotic Dehydration: Immersing pumpkin slices in hypertonic sugar or salt solutions before drying removes some water and can improve cell wall strength, reducing shrinkage and enhancing rehydration.

Chemical Treatments: Soaking in solutions like calcium chloride can strengthen cell walls, thereby reducing collapse during drying and improving rehydration texture.

- Particle Size and Cut Shape

The physical form of dried pumpkin affects rehydration kinetics and final texture:

Fine powders or granules rehydrate faster due to increased surface area, suitable for beverage powders, purees, or bakery mixes. However, powders tend to lose the fibrous texture.

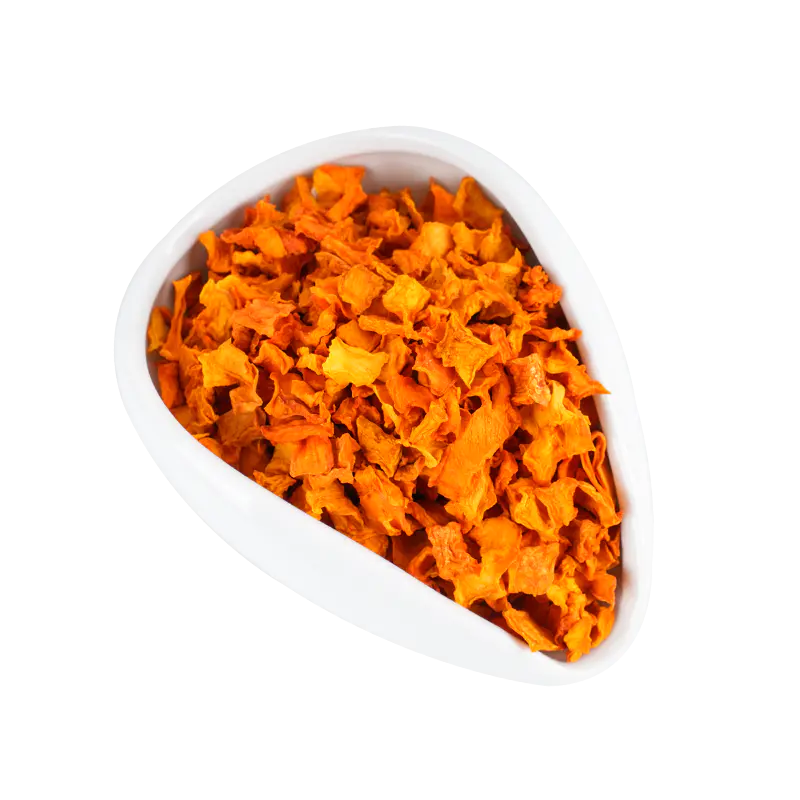

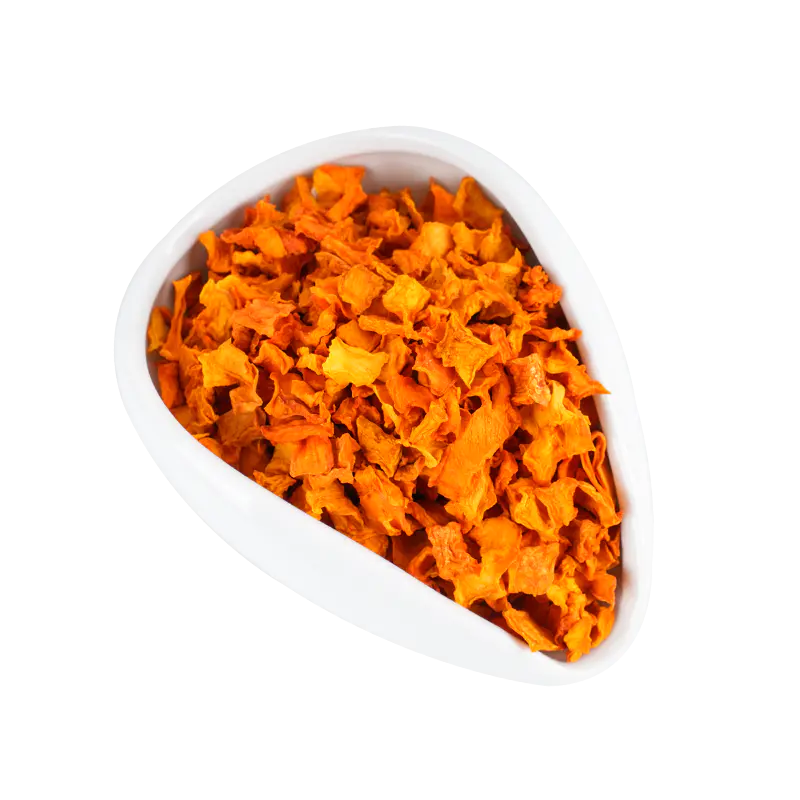

Slices, cubes, or flakes retain more natural structure, providing a meatier texture after rehydration. These forms are preferable for soups, stews, or snack products where mouthfeel is important.

Optimizing particle size depends on the end use and consumer expectations.

- Control of Final Moisture Content and Water Activity

Final moisture content influences both shelf life and rehydration performance:

Overdrying (very low moisture) can cause hardening and cell wall damage, reducing water absorption capacity.

Insufficient drying leaves high residual moisture, increasing spoilage risk.

Target moisture content for dried pumpkin is typically 5–10%, balancing shelf stability and rehydration ability.

Water activity (a_w) below 0.6 is generally required to inhibit microbial growth and enzymatic reactions, protecting product quality during storage.

- Packaging and Storage Conditions

Post-drying handling affects how well the product maintains its rehydration properties:

Packaging: Moisture-proof, oxygen barrier packaging prevents moisture uptake and oxidation, preserving the porous structure necessary for rehydration.

Storage: Cool, dry, and dark storage prevents degradation of nutrients and texture.

Poor storage conditions lead to caking, microbial contamination, and reduced rehydration performance.

- Rehydration Process Optimization

The conditions under which dried pumpkin is rehydrated can be optimized to restore desired qualities:

Temperature: Warm water (40–60°C) facilitates faster water penetration and softening, improving texture without cooking the product excessively.

Time: Adequate soaking time ensures full hydration; too short results in a dry, tough product, too long may cause nutrient leaching.

Agitation: Gentle stirring or shaking during rehydration improves water contact and speed.

Water-to-product ratio: Sufficient water volume ensures complete absorption and avoids concentration of solutes.

- Use of Functional Additives

Incorporating hydrocolloids or texturizing agents during drying or rehydration can improve the mouthfeel and stability of rehydrated pumpkin:

Ingredients such as gums (xanthan, guar), starches, or pectin may help mimic fresh texture.

Enzymatic treatments can modify fiber to enhance softness and rehydration rate.

- Tailoring for Specific Culinary Applications

Soups and Purees: Require fully rehydrated, soft pumpkin with smooth texture. Freeze-dried powders or small granules are preferred for quick dispersion and blending.

Baked Goods: Dry pumpkin powders or flakes that rehydrate during baking can add flavor and nutrition without excess moisture.

Snacks: Dried pumpkin pieces with moderate hardness may be consumed directly or after light rehydration.

Ready-to-Eat Meals: Controlled rehydration ensures the pumpkin complements other ingredients in texture and taste.

Optimizing the rehydration properties of dried pumpkin requires an integrated approach involving selection of appropriate drying technologies, precise control of drying and pre-treatment parameters, and tailored rehydration protocols. Freeze-drying offers superior rehydration but at higher cost, while hot air drying suits certain applications where texture firmness is acceptable. Pre-treatments like blanching and osmotic dehydration improve quality, while packaging and storage preserve product integrity. Finally, rehydration conditions can be adjusted to meet the needs of diverse culinary uses, enabling dried pumpkin to serve as a versatile ingredient in the food industry.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168