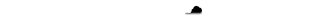

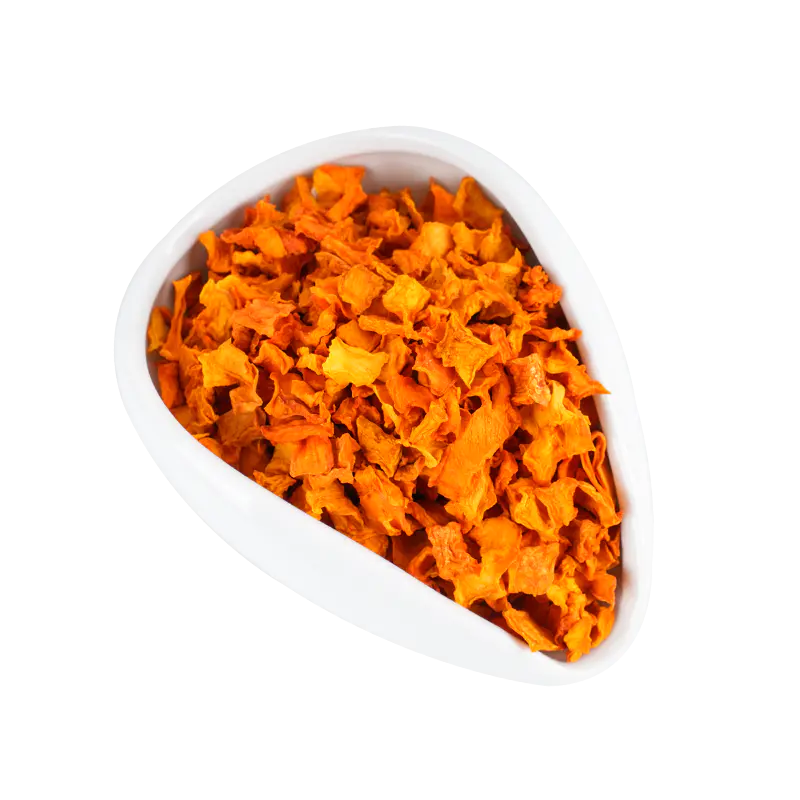

As a deep-processed form of pumpkin products, dried pumpkin has gained increasing attention from consumers and food processing enterprises due to its convenience in storage, transportation, and diverse applications.

I. Drying Methods for Dried Pumpkin

Drying is a key step in the deep processing of pumpkin, directly affecting the final product’s quality, nutrition, and shelf life. Common drying methods include sun drying, hot air drying, and freeze-drying.

1. Sun Drying

Sun drying utilizes solar heat and natural wind to evaporate moisture from pumpkin slices. This method is simple and low-cost but comes with several drawbacks:

Slow drying speed, easily leading to surface oxidation and discoloration.

Significant nutrient loss.

Difficult to control environmental conditions, susceptible to weather and pollution.

Inconsistent product quality, fluctuating moisture content, and short shelf life.

Therefore, sun drying is mainly used in small-scale or household production and cannot meet the requirements of modern food industry standards.

2. Hot Air Drying

Hot air drying is a widely adopted industrial drying method. It uses constant-temperature circulating hot air to rapidly remove moisture from pumpkin. Key features include:

Short drying time, high efficiency, suitable for large-scale production.

Better control over temperature and humidity, ensuring uniform drying.

Under appropriate temperatures (typically 50–70°C), it minimizes nutrient loss.

The dried pumpkin has a relatively hard texture, facilitating storage and transport.

However, some heat-sensitive vitamins — especially vitamin C and certain B vitamins — may still degrade during the process.

3. Freeze-Drying (Lyophilization)

Freeze-drying involves freezing the pumpkin first, then removing moisture through sublimation under low temperature and vacuum conditions. Its advantages are:

Best preserves the original shape, color, flavor, and nutritional components of pumpkin.

Excellent rehydration properties, with texture close to fresh pumpkin.

Extremely low moisture content (usually 1–3%), significantly extending shelf life.

No need for preservatives, offering high safety and quality.

The main disadvantages are high equipment investment and processing costs, along with longer production cycles, making it more suitable for premium dried pumpkin products.

II. Moisture Content and Shelf Life of Dried Pumpkin

1. Moisture Content

Moisture content is a critical indicator reflecting the degree of drying and storage stability. Different drying methods result in varying levels of moisture:

Sun-dried pumpkin: Approximately 10–15% moisture; prone to mold and spoilage due to incomplete drying.

Hot air-dried pumpkin: Typically 8–12% moisture.

Freeze-dried pumpkin: Lowest moisture level, generally 1–3%, making it the driest among the three.

Lower moisture content means longer shelf life and reduced microbial growth risk.

2. Shelf Life

The shelf life of dried pumpkin depends on moisture content, packaging conditions, and storage environment:

Sun-dried pumpkin: Usually lasts 3–6 months.

Hot air-dried pumpkin: Shelf life ranges from 6–12 months.

Freeze-dried pumpkin: Due to extremely low moisture, can last over 12 months, and up to 18–24 months under optimal conditions.

It is recommended to store dried pumpkin in a dry, cool, and dark environment. Sealed packaging further extends shelf life.

III. Nutritional Composition and Retention of Dried Pumpkin

Pumpkin is naturally rich in various nutrients, including β-carotene (a precursor of vitamin A), vitamin C, dietary fiber, minerals (potassium, magnesium, iron), and multiple antioxidants. The retention of these nutrients during drying varies:

1. Vitamin Content

Vitamin C: Highly sensitive to heat and light; partially lost during hot air drying, better preserved in freeze-dried products.

β-Carotene and Vitamin A: Relatively stable, minimal loss during drying, especially well-retained in freeze-dried versions.

B Vitamins: Some degradation occurs, but the impact is minor.

2. Dietary Fiber

Dietary fiber structure is stable, and drying has little effect. Dried pumpkin retains high dietary fiber content, which benefits intestinal health.

3. Minerals

Mineral elements are not volatile and remain largely unaffected by drying processes. Dried pumpkin remains rich in essential minerals.

4. Antioxidants

Some antioxidant compounds may degrade during drying. Freeze-drying best preserves their integrity.

In summary, freeze-drying best retains pumpkin nutrition, followed by hot air drying, while sun drying results in the greatest nutrient loss. Consumers can choose according to their needs.

IV. Applications of Dried Pumpkin in Food Processing and Cooking

Due to its convenience and nutritional value, dried pumpkin is widely used in both food industry and home cooking.

1. Snack Production

Seasoned dried pumpkin slices or cubes make healthy snacks popular among young consumers. They offer crisp texture and rich nutrition, ideal as meal replacements or healthy treats.

2. Soup Ingredients and Stews

Used as soup ingredients, dried pumpkin quickly regains softness after cooking, enhancing sweetness and nutrition. Suitable for making pumpkin soup or stews.

3. Baking Ingredient

Pumpkin powder or diced pieces can be added to bread, cakes, cookies, and other baked goods, improving flavor and nutritional value — especially suitable for pumpkin-flavored pastries.

4. Beverage Ingredient

Pumpkin powder can be mixed into nutritious drinks, smoothies, or meal replacement powders, offering convenience and health benefits.

5. Instant Food Ingredient

Dried pumpkin is widely used in instant noodles, ready-to-eat porridge, and similar products as a nutrition-enriching ingredient.

V. Safety Testing and Quality Assurance of Dried Pumpkin

Food safety is one of the most important concerns for consumers. As a food raw material and snack, dried pumpkin must meet strict safety standards.

1. Heavy Metal Testing

Heavy metal contamination risks in raw pumpkin mainly come from soil and environment. Qualified manufacturers test raw materials for heavy metals such as lead, arsenic, cadmium, and mercury, ensuring compliance with national food safety limits.

2. Pesticide Residue Testing

Pesticides may be used during pumpkin cultivation. Residues are tested before processing to ensure compliance with regulatory standards and consumer health protection.

3. Microbial Testing

Although low moisture content inhibits microbial growth, products still undergo testing for E. coli, molds, and yeasts to prevent food safety risks.

4. Third-Party Inspection Reports

Independent third-party laboratories inspect heavy metals, pesticide residues, and microbial indicators of dried pumpkin, issuing official reports that enhance product credibility and consumer confidence.

VI. Frequently Asked Questions About Dried Pumpkin

How to Identify High-Quality Dried Pumpkin?

High-quality dried pumpkin should have natural color, no off-odor, uniform texture, no impurities, moderate moisture content, and good nutrient retention.

Does Dried Pumpkin Contain Preservatives?

Legitimate products do not require preservatives; proper drying and vacuum packaging allow long-term storage.

How to Store Dried Pumpkin?

Keep sealed in a cool, dry place away from moisture, high temperatures, and direct sunlight to prevent spoilage.

Is There a Big Nutritional Difference Between Dried and Fresh Pumpkin?

Dried pumpkin has concentrated nutrients but may lose some heat-sensitive vitamins. Overall nutritional value remains high.

Who Is Suitable for Consuming Dried Pumpkin?

Ideal for individuals pursuing healthy diets, those needing dietary fiber and vitamin A supplementation — suitable for children, elderly people, and those managing weight.

VII. Conclusion

Dried pumpkin plays an important role in modern food processing due to its diverse drying techniques, stable nutritional profile, and broad application scenarios. Choosing the appropriate drying method and ensuring rigorous safety testing are key to maintaining product quality and health benefits. When purchasing, consumers should pay attention to moisture content, nutrient retention, and safety inspection reports, and store properly to maintain freshness. Continuous innovation and promotion of dried pumpkin contribute to the development of green and healthy food industries.

For more information or product details, please feel free to contact us:

E-mail: [email protected]

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168