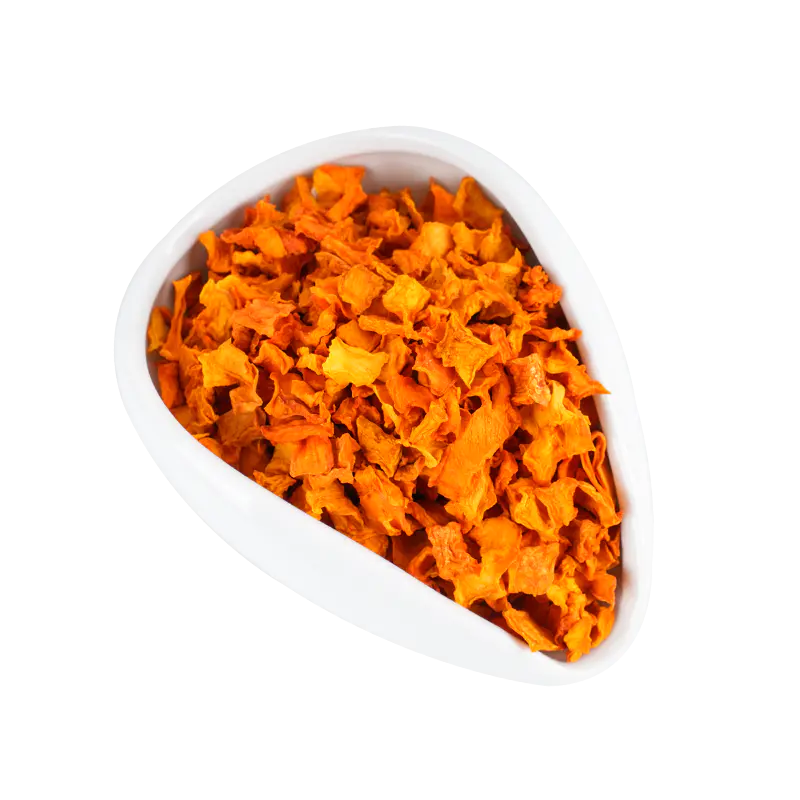

Coriander, known both for its aromatic leaves and flavorful seeds, is one of the most widely used herbs in global cuisine. While fresh coriander has a bright and distinct aroma, its shelf life is limited, making it difficult to transport and store for long periods. To meet the needs of food processors, spice companies, and international markets, coriander is often preserved in dehydrated form. Dehydrated coriander not only extends storage life but also allows for easy packaging, transportation, and use in recipes without losing its characteristic flavor.

Producing dehydrated coriander requires careful selection of drying methods to balance cost, efficiency, and quality. Different dehydration techniques influence the color, aroma, and nutritional value of the final product. Below are the most commonly used methods.

Content

Air Drying

Air drying is one of the oldest and most cost-effective methods of producing dehydrated coriander. It can be carried out in two primary ways:

Sun Drying: Fresh coriander leaves or seeds are spread out in thin layers under direct sunlight. This method requires little equipment and is widely used in regions with hot, dry climates. However, it is highly dependent on weather conditions, may lead to uneven drying, and exposes the product to dust and contamination.

Hot-Air Drying: To overcome the drawbacks of sun drying, many producers use hot-air drying chambers. These systems circulate warm air at controlled temperatures, allowing coriander to dry more evenly and hygienically. While this method helps retain more flavor compared to open-air drying, prolonged heating can still lead to some loss of volatile oils.

Air drying is popular for large-scale commercial production where cost efficiency is the priority.

Oven Drying

Oven drying is another commonly used method, particularly for small to medium-scale operations. Fresh coriander is placed on trays and dried at controlled temperatures inside an oven. The process is more hygienic and consistent compared to open-air drying, making it suitable for packaged food production.

The main drawback is that extended exposure to high temperatures may reduce essential oils and aroma compounds. Careful temperature control is required to preserve flavor while achieving the desired moisture reduction.

Freeze Drying

Freeze drying, also known as lyophilization, is one of the most advanced dehydration methods. In this process, coriander is first frozen, and then subjected to low pressure, allowing ice to sublimate directly into vapor without passing through a liquid phase.

This method retains the original color, aroma, and nutritional content of coriander far better than heat-based drying methods. The resulting product is lightweight, easy to rehydrate, and very close to the quality of fresh coriander. However, freeze drying requires expensive equipment and higher energy consumption, making it more suitable for premium or export-oriented products.

Microwave Drying

Microwave drying uses microwave energy to remove water quickly from coriander leaves or seeds. This technique is much faster than conventional drying and can preserve more aroma compounds. Since the heating is volumetric, moisture is removed more uniformly compared to surface-only methods.

The challenge with microwave drying is maintaining control, as uneven heating can damage delicate leaves. Despite this, it is increasingly used in food industries where speed and quality retention are both important.

Vacuum Drying

Vacuum drying is another modern method that removes moisture under reduced pressure. By lowering the boiling point of water, dehydration can be achieved at relatively low temperatures, which helps protect flavor, aroma, and nutrients.

Compared to freeze drying, vacuum drying is more energy-efficient and less costly, making it a practical option for high-quality coriander that still needs to be competitively priced.

Choosing the Right Method

The choice of dehydration method depends on the target market and application:

For bulk, low-cost production, air drying and oven drying are preferred due to affordability.

For premium food products and exports, freeze drying offers the best quality retention.

For balanced efficiency and quality, vacuum drying is often selected.

For fast, small-batch processing, microwave drying provides a practical solution.

Conclusion

The production of dehydrated coriander relies heavily on the chosen drying method, as each approach affects the final product’s flavor, aroma, appearance, and shelf life. While traditional air drying remains the most economical, advanced techniques such as freeze drying and vacuum drying are increasingly used to meet the growing demand for high-quality, export-ready coriander.

By applying the right dehydration technology, producers can deliver coriander that balances cost-effectiveness with flavor preservation, ensuring that this essential herb continues to enrich cuisines worldwide in both fresh and dehydrated forms.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168