Maintaining the natural color, flavor, and nutritional profile of vegetables during the dehydration process to create powders presents several challenges. These challenges are largely due to the inherent properties of vegetables, the methods used in dehydration, and the changes that occur in the process. Here's a breakdown of the main challenges:

Content

1. Color Retention

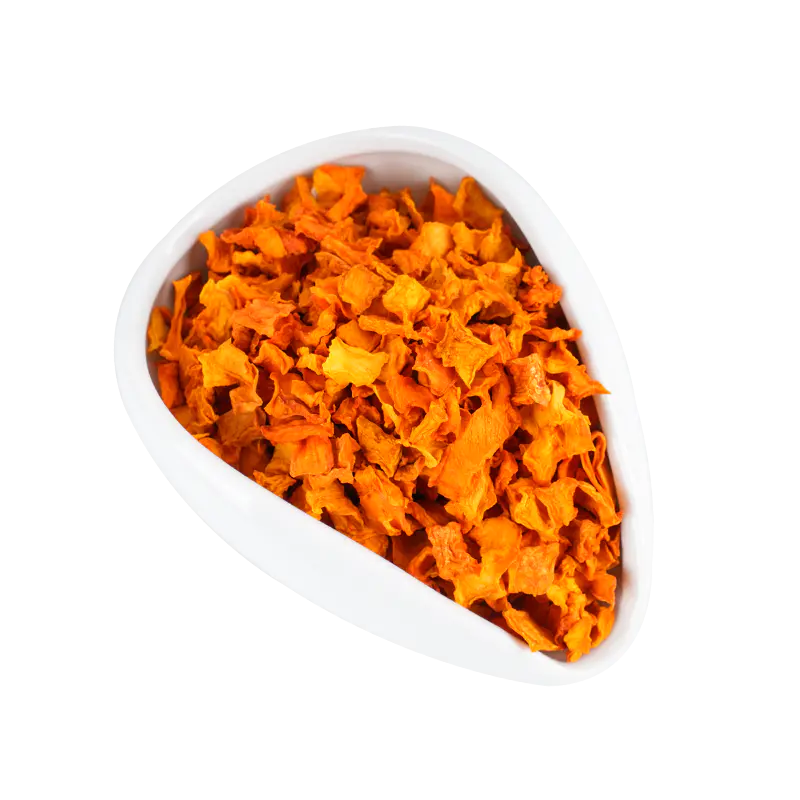

Vegetables undergo significant changes in color during dehydration, primarily due to the loss of water and the breakdown of certain pigments. Key factors affecting color retention include:

-

Heat Sensitivity: Many vegetables contain heat-sensitive pigments (such as chlorophyll in green vegetables and carotenoids in orange and yellow vegetables) that can degrade during drying. Heat-based dehydration methods, like air-drying or spray-drying, can cause color fading or browning.

-

Enzymatic Browning: Before dehydration, enzymes naturally present in vegetables (such as polyphenol oxidase) can react with oxygen, causing browning. This reaction can lead to an undesirable color change in the powder. To combat this, vegetables may need to be blanched before drying, which can help inactivate enzymes but may also result in some nutrient loss.

-

Oxidation: Exposure to oxygen during drying can oxidize certain compounds, leading to color degradation, particularly in vegetables that are high in flavonoids or other antioxidants.

2. Flavor Preservation

Vegetables contain volatile compounds that contribute to their distinct flavors. During the dehydration process, these flavors can be altered or diminished, resulting in a powder that may not fully reflect the fresh vegetable's taste. Key challenges include:

-

Loss of Volatile Compounds: Aromatic compounds, which are responsible for the flavor of fresh vegetables, can be lost during drying due to their volatility. Heat, oxygen, and extended drying times can all contribute to the breakdown of these compounds, which may lead to a reduction in the vegetable's flavor intensity.

-

Maillard Reaction: In some dehydration processes, especially those involving high heat (e.g., air drying or spray drying), the Maillard reaction can occur, causing a shift in flavor and potentially creating undesirable bitter or roasted notes.

-

Temperature Sensitivity: Some flavor compounds are sensitive to high temperatures. For example, vegetables high in sulfur compounds (like broccoli or onions) may lose their distinct flavor under high heat, resulting in a less vibrant or altered taste profile in the powder.

3. Nutritional Retention

Dehydration can also lead to a loss of essential nutrients, particularly those that are sensitive to heat, light, or air. Key challenges in maintaining the nutritional profile include:

-

Vitamin Loss: Vitamins, particularly water-soluble ones like vitamin C and B vitamins, are highly susceptible to degradation during dehydration. High temperatures and prolonged drying times can accelerate the loss of these nutrients. For instance, vitamin C is sensitive to heat and oxidation, meaning it can degrade during the drying process.

-

Antioxidants: Vegetables are rich in antioxidants, such as carotenoids and polyphenols, but these compounds are sensitive to oxidation and heat. While some antioxidants, like lycopene in tomatoes or beta-carotene in carrots, may be relatively stable, others are more prone to degradation during drying.

-

Mineral Retention: Although minerals are generally stable during dehydration, the concentration of minerals can increase in the powder due to the removal of water. However, the overall mineral content might be affected by washing or processing steps, which can lead to some mineral loss.

-

Fiber Integrity: While dehydration generally preserves the fiber content of vegetables, the breakdown of plant cell walls during the drying process could affect the texture and digestibility of the fiber. This can result in a powder with less desirable mouthfeel or a reduction in functional benefits like satiety.

4. Moisture Content and Powder Stability

Once vegetables are dehydrated into powders, maintaining their stability becomes a significant challenge:

-

Hygroscopic Nature: Dehydrated vegetable powders are highly hygroscopic, meaning they readily absorb moisture from the air. This can cause the powder to clump, lose its free-flowing consistency, or become susceptible to microbial contamination or spoilage.

-

Powder Consistency: Achieving a consistent particle size and maintaining an even moisture content are crucial for ensuring uniform rehydration and preventing changes in texture or taste when the powder is used in food products. Inconsistent drying can lead to a powder with uneven solubility and reduced quality.

5. Processing Time and Efficiency

To minimize the impact on color, flavor, and nutrition, it's essential to control the processing time and method of dehydration. However, achieving this balance presents the following challenges:

-

Dehydration Method Selection: The method chosen for dehydration (e.g., freeze-drying, spray drying, or air drying) can have a significant impact on the final product. While freeze-drying preserves most of the nutrients, flavor, and color, it is more expensive and time-consuming compared to spray-drying or air-drying, which can result in higher nutrient loss.

-

Energy Efficiency: Some drying processes, especially those that use high temperatures (such as air drying), can be energy-intensive, leading to increased production costs. This trade-off between efficiency and quality preservation is a challenge in large-scale commercial production.

6. Packaging and Shelf Life

Even after drying, the packaging and storage conditions of dehydrated vegetable powders are critical to maintaining their quality:

-

Exposure to Light and Oxygen: Light and oxygen can cause further degradation of nutrients, flavor, and color over time. Proper packaging with vacuum sealing or argon flushing can help mitigate these issues, but it adds to the cost and complexity of production.

-

Temperature Sensitivity: High temperatures during storage can accelerate the degradation of sensitive nutrients, making temperature-controlled storage necessary to extend shelf life and maintain the nutritional and sensory qualities of the powder.

English

English 中文简体

中文简体

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China

Xinqian Village (Dehydrated Fruit and Vegetable Industrial Park), Duotian Street, Xinghua City, Taizhou City, Jiangsu Province, China +86-13852647168

+86-13852647168